Can pollution-eating building materials make a dent in urban NOx levels?

POLLUTION-eating building materials have been a feature of one or two high-profile construction projects this year, and one supplier has urged the government to provide funding to incentivise greater take-up of the technology in UK construction.

Photocatalytic materials – in products like cement or tiles – can be used on roads and buildings to remove excess levels of nitrogen dioxide (NO2) and nitric acid from the air. Fingered by health authorities as a cause of respiratory and heart problems, NO2 is the pollutant pinpointed in April’s Supreme Court ruling against the government, mandating immediate action to redress its failure so far to keep levels within limits set out by the EU’s Air Quality Directive.

Photocatalytic technology is already used in cement on pavements in Japan, the US and the Netherlands. And it can also be used for roofing tiles, road construction and in highway sound buffering structures. Roofing and facades specialist Marley Eternit, a UK supplier of tiles impregnated with photocatalytic materials, suggested in May that the government

ought to follow the lead of Japan and the Netherlands in providing financial incentives for the use of these materials.

Gavin White, product manager at Marley Eternit, said: “The UK is in breach of its air pollution targets in 16 areas, mainly busy cities. “If it only addresses the polluter, rather than the pollution itself, then the UK is missing a trick.

“A better option is to take a two pronged approach and also look to reduce the amount of pollution that is still being produced with the use of photocatalytic technology on our buildings and roads to absorb the toxic mix of NOx generated by road traffic exhaust fumes.

Where is it being used?

High profile deployments of photocatalytic technology this year have included the pavilion at Milan’s Expo 2015 world’s fair (see image, above), which opened in May. It has been constructed with 9,000 square meters of photocatalytic concrete, arranged in an eyecatching design intended to recall the shapes of branches in a forest. Architect Nemesi & Partners has employed Biodynamic cement developed by the Italcementi Group in the design.

In addition to the photocatalytic materials, the mortar is said to be made from 80% recycled aggregates, part of which – according to Italcementi – consists of “scraps from the cutting of Carrara mar- ble”, providing a brilliance not found in traditional white cements.

Another architecture firm, Berlin- based Elegant Embellishments, has deployed tiles coated with titanium dioxide in a hospital building in Mexico City called the Torre de Especialidades which features a 100-yard-long façade made with the tiles.

This kind of pollution-eating capability has also featured in TioCem cement, launched in the UK in 2008, and available from Hanson Cement, based on technology licensed from Italcementi. Marley Eternet launched its Eco- logic range of tiles in 2007. Incorporated in the company’s Ludlow Major tile, said to be a “simple, neat and cost effective roof cov- ering”, which has been popular in social housing projects, it is manufactured using more than 50% re- cycled materials.

How does it work?

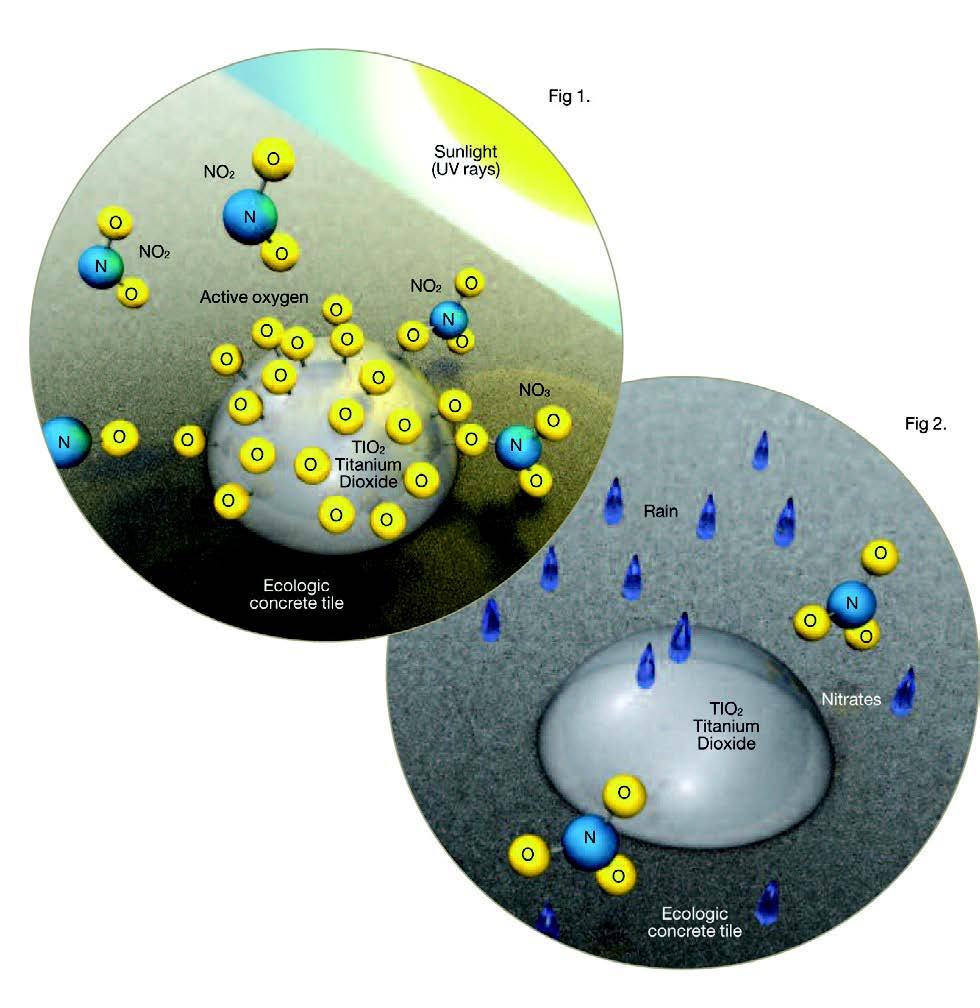

Marley Eternit describes the technology as using an embedded layer of titanium oxide, which in the presence of UV light creates ac- tive oxygen, which in turn oxidises NOx to form soluble nitrate. Initial- ly this nitrate forms nitric acid, but it soon reacts with excess levels of calcium carbonate in the cement to form calcium nitrate, a plant fertiliser which is washed away with rainwater. The firm suggests the water soluble nitrates could even be stored in a rainwater harvest- ing system and used to water and help fertilise a garden.

In this product the titanium dioxide is incorporated in granular form, to maximise the photocatalytic area. During manufacture, the granules are embedded into a slurry, which cures to fix them in place.

How much NOx does it remove?

Marley Eternit provides estimates of NOx removal levels for its Ecologic tiles. Using “typical data on pollution levels in urban areas and laboratory test data”, the firm says that over the lifespan of an average sized roof, the tiles will remove a quantity of NOx equivalent to that emitted by a modern car cover- ing over 100k miles. The firm also cites a study in the Netherlands that found photocatalytic concrete decreased NOx levels by 25%, and by as much as 45% in ideal

weather conditions, in an area of busy roads.

oxygen, which in turn oxidises NOx in the air to form soluble nitrate

The amount of pollutants removed from the atmosphere by photocatalytic materials is de- pendent on weather conditions. Where the Tiocem product is concerned, supplier Hansom Cement says that in sunny weather up to 90% of pollutants (nitrogen oxides and a few others) can be eliminated from the atmosphere, while when the sun isn’t shining, it still removes 70% of pollutants.

Marley Eternet says the concentration of nitrates in the run-off generated by the tiles will not reach a damaging level. “Even for the driest areas of the UK we estimate that additional levels of nitrate will not average more than 1mg/L or peak at more than 14mg/L,” says the firm’s website. For comparison, rivers with water catchments in agricultural areas often exceed 25mg/L whilst the EU permissable maximum for drinking water is 50mg/L.

The coating on the Ecologic tiles is said to continue absorbing pollutants for 25 years.