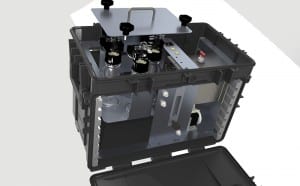

ITALIAN instrument maker ETG Risorse has released a portable syngas pre-treatment unit. The device provides clean gas for analysis by removing tar and dust.

Syngas frequently contains moisture, particulate matter, and even corrosive gases. It is important to remove these constituents from the sample gas before analyzing it. In some cases, the produced gas being presented for analysis contains a variety of contaminants that should be removed from the sample prior to allowing it to enter the analyzer. Gasification plants that have municipal waste as their feedstock are frequently in this category.

A scrubber water wash system (bubbler) thoroughly mixes the sample and runs it through a specialized column of water. This dissolves any water-soluble contaminants and will eliminate any residual solids from the sample.

The unit is fully transportable and can receive a direct inlet from the process gas source (examples include reactor, pyrolysis, coal, or other dirty process gas sources). There are three refillable water scrubbers, one fine filter with replaceable 0.3µm filter element for tar removal, and a heat exchanger made of PVDF. There is a semiconductor (peltier-effect) cooled, electronic controller. Parameters include a temperature setpoint at +5° C. Other elements include a built-in heat exchanger temperature display, a micro fine dust filter with fiberglass filter element, a built-in peristaltic pump for continuous removal of condensate, a diaphragm sample pump PVDF/FPM, flow rate < 2Nl/min interlocked with over/under temperature alarm, “Pump” and “Alarm” status display, flowmeter with needle valve, LED indicator lamp, blinking when system is ready for use.

The materials in contact with the sample are PVDF, FEP, FPM and SS316.

Syngas (synthesis gas) refers to a gas mixture that contains varying amounts of carbon monoxide, hydrogen and very often CO2. Production methods include steam reforming of natural gas or liquid hydrocarbons to produce hydrogen, partial oxidation, the gasification of coal, biomass, and in some types of waste-to-energy gasification facilities.

The name comes from its use as an intermediary in creating synthetic natural gas and for producing ammonia or methanol.