The Internet of Things, big data and analytics offer the promise of better business decision making. Finnish sensors developer Enevo is one firm leveraging this technology in the area of waste management and recycling, recently assisting the municipality of Rotterdam (Rotterdam City Management, Stadsbeheer) to achieve tangible results through more efficient collections and route planning, as this case study outlines.

Rotterdam, the second largest city in the Netherlands, considers itself to be an enthusiastic adopter of innovation and technology when it comes to meeting the challenges which many municipalities face. With a population of around 620,000 inhabitants, it is an important commercial and cultural centre, as well as being one of the busiest container ports in the world. However, where there are people, there is also waste. Consequently, the municipality of Rotterdam looks for innovative solutions to help drive efficiencies and utilise the city’s waste budget more effectively.

Rotterdam is also engaged in the Netherland’s circular economy. As such it is highly focussed on recycling materials and waste. The city’s leaders have a strong belief that clean streets are a major factor in fostering a positive attitude in their communities, and its proud boast is that less than one percent of its waste ends up in landfill. To facilitate this, Rotterdam has installed 4800 underground waste containers for residential waste, together with a further 650 for paper and cardboard and a similar number for glass.

Rotterdam’s waste management challenge

Multi-storey, residential apartment complexes which house up to 70 percent of Rotterdam’s inhabitants have made it practical to develop a range of community-centred, waste collection sites across the city. This has eliminated tens of thousands of individual household waste containers from the city streets. However, it has also created a requirement the municipality of Rotterdam to ensure that the underground containers are emptied reliably, preventing the build-up of waste materials left in the streets.

Joost van Maaren, manager of Waste Collection and Recycling in Rotterdam commented, “Since all waste has to be dealt with within the confines of the municipality, separation of waste fractions is important. However, to be able to make the most of the recycling and reuse opportunity, we need to make sure that waste collection is convenient for citizens. That means optimising the waste value chain, from the number and placement of receptacles, to scheduling collections to ensure there’s always space in the containers.”

Until recently, most waste containers for single stream fractions were collected based upon a static route plan. This meant fixed collection points on regular routes. Municipality of Rotterdam had identified fixed routes as a source of inefficiency, which had been partially rectified by manually monitoring fill rates for individual containers and adjusting collections accordingly. However, it was felt that collection efficiency could be further improved upon. In commissioning the pilot project, the municipality of Rotterdam set Enevo and TWS a target to increase the efficiency of waste collection by at least 20 percent.

Charting a course to improved efficiency

Joost van Maaren said: “Fill level measurement is a well understood principal in the waste industry. However, we believed that if we could combine this data with a dynamic route planning system, it could possibly be very beneficial. To achieve this, we needed to understand where and when containers reach the optimum fill level and needed emptying, and then target collections to those sites. We believed that dynamic route planning would be key to unlocking this advance in waste management efficiency.”

After researching the market for the most appropriate technology for a pilot scheme the Waste Collection and Recycling Team chose Enevo, a leading innovator in waste collection technology and its Dutch service company, Total Waste Systems (TWS) as the scheme’s development partners. During the approval process, a working group from Stadsbeheer Rotterdam visited three other Dutch cities where Enevo and TWS are operating similar waste collection projects.

The development team for this project consisted of a steering group of senior managers, to establish the criteria and parameters for the project, and a working group. The working group included members from various involved disciplines, including waste, finance, administration, ICT, and a member from TWS. This team met every month during the pilot.

Prior to the start of the project with Enevo, the waste department had already improved the collection cycle for this waste stream through meticulous manual tracking of container fill levels. This information was recorded and created the baseline for the project. Paper and cardboard fraction waste was selected, due to its recycle value and the amount of fill level data already available for pre- and post-project analysis.

Adding intelligence and cloud-based fill-level monitoring

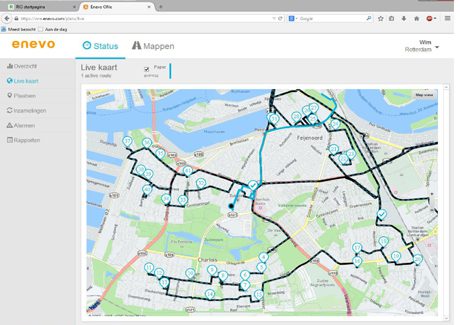

For the pilot project, Enevo’s wireless sensors were installed in 150 paper and cardboard fraction collection containers in South Rotterdam. These sensors continuously monitor the fill level within the containers and were linked to the waste department’s project office via Enevo cloud servers. As well as monitoring the fill level and rate of fill of the container, they also register location as well as temperature, which could indicate if the contents have caught fire – a rare but possible event.

Another useful monitoring function was the ability to use the Enevo ONe data to detect when a container had an obstruction in or near its opening. Understanding this kind of situation has allowed the team to develop processes that ensure fast response to these conditions.

The agreed project area was serviced by a single collection truck operating five days per week. The truck is a single operator vehicle, which lifts the waste container out of the ground and deposits the waste directly into the storage area of the truck, a contained and efficient collection method. Each waste container has a 4 cubic metre capacity; during the pilot it was discovered the optimum fill level between collections was 70 percent, which ensured no container overflow. Although in some instances fill levels of 90 percent were recorded without incident.

Dynamic collection planning brings efficiency gains

Key to the project was the installation of the Enevo Smart Plans dynamic collection route planning system. Data is collated during the day from all the sensors in the pilot area. Fill levels and fill rates are compared to trend data to predict the future waste collection needs. The system then analyses millions of possible collections options and provides the most optimal collection route, maximising resource efficiencies while minimising distance travelled and avoiding any container overfill scenarios. The plan for the next day’s collections is downloaded to a tablet pc in the truck, for the driver to follow the route to the collection sites.

Once the project was up and running a second working group, which included drivers, was established to feedback direct experience of operating to the dynamic collection routes. Driver input was found to be invaluable in developing the route planning element of the project with custom map layers being coded to tailor the routes to the collection vehicles.

“Of-course Enevo supplied the technology, but the experience of our drivers – and their enthusiastic participation in the pilot scheme – was a vital factor in developing a solution which works effectively and efficiently for Rotterdam. Our drivers are very complimentary about the system and they say they don’t want to go back to the old ways of managing waste collections,” said Joost van Maaren.

Targets achieved and exceeded

Commenting on the results of the pilot, Joost van Maaren stated, “We found by monitoring fill rates, we had the opportunity to reduce the number of collection days, we found that we were easily able to meet the target of a 20 percent reduction”.

The Rotterdam pilot has demonstrated that by embracing technology and partnering with Enevo, a flexible waste monitoring, collection and recycling process can deliver significant returns for the city. The pilot proved that using near real time data to predict fill level and fill rates coupled with dynamic collection route optimisation can achieve significant operational benefits across a spectrum of criteria including reducing overall waste collection costs, carbon foot print, traffic reduction, less vehicle maintenance, as well as providing high value waste collection data. In addition, the city of Rotterdam maintains a clean and pleasant environment for it’s residents and visitors.

In March 2016, it was agreed to expand the pilot project to cover 40 percent of Rotterdam’s paper and cardboard waste collection containers. Summing up, Joost van Maaren said: “We’re very happy working with Enevo. We feel that the combination of Enevo technology and the knowledge and expertise of our waste collection team has resulted in an effective solution for the city. Using Smart Plans we’ve increased the mean fill level of container sites saving us time, fuel, service costs and emissions. Like Rotterdam, the solution is innovative, renewable, and efficient.”