Transferring untreated wastewater and effluent from locations where there is insufficient gravity flow into a mains sewer can cause big problems for operators of pump stations.

The main difficulty is contending with pump and system failure due to pumps becoming blocked with solids. Screening can, to a certain degree, remove large objects, but it is the steady build-up of matter that is often the main cause of pump failure. Removing blocked matter is time-consuming and costly – and thoroughly unpleasant – and often has to be undertaken as an emergency.

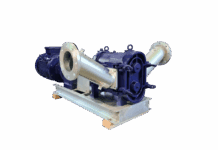

To tackle the issue, KSB has developed a wastewater pump station package that includes a patented dry-installed solids separation system. It ensures that the transfer pumps do not become clogged or damaged due to the presence of the upstream separator. The AmaDS³ has been designed specifically for buildings and complexes that require the availability of a wastewater/effluent pumping station at all times. Providing economic operation and system reliability, the AmaDS³ is a combination of a closed gas tight separation system and two wastewater pumps (one duty and one standby) in a back pull-out design.

It functions by allowing untreated wastewater/effluent to flow into the unit whereupon it enters the separator. This collects solids but allows the water to drain through into a collecting tank where it is held until a preset level is reached. Once that level has been reached, the intake check valve is closed and the duty pump is automatically started, pumping the treated water into the discharge line and through the separator, in the process flushing the solids out into the discharge line and out of the pump station. Once this process has been completed and the water level in the collecting tank is back at a minimum level, the intake check vales opens and wastewater/effluent starts to flow into the separator.