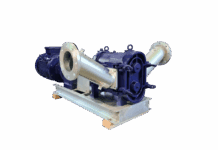

The company, which designs and manufactures progressing cavity pumps, Munchers and associated equipment, has announced that the largest EZstrip transfer pump now has a 225m3/h capacity, widening its reach in wastewater applications.

The EZstrip products were designed to incorporate the best elements of the company’s Compact C Range pumps. The technology on which they are based is said to provide a quick and easy way to disassemble, de-rag and maintain a pump in-situ. The time required to replace a rotor, stator, coupling rod and drive train can be reduced by up to 95%, cutting a typical day-long maintenance operation down to just 30 minutes.

“Before we designed and launched the original EZstrip pumps we listened very carefully as our waste water industry customers described the typical problems they faced,” explained group sales and marketing director Simon Lambert. “They told us that ragging was becoming a serious problem because of an increasing volume of unsuitable items finding their way into the sewers. They wanted a pump that would minimise downtime in a significant way and the new EZstrip range was our response.”

The new products have handling capacities of 94m3/h, 140m3/h and 225m3/h and can be installed in new plants or retrofitted into existing Compact C applications. Electrical disconnection is not required and suction and discharge pipes remain untouched. No special tools or skills are required for normal de-ragging operations.