Water treatment engineers are improving the efficiency of their maintenance work with the help of a new water-monitoring device, according to its makers

DESIGNED primarily to measure water quality, the Intellisondes devices from Intellitect Water also measure flow, and this reading is being used to detect the accumulation of debris that necessitates a maintenance visit.

Wastewater treatment efficiency is often measured by the analysis of treated water which is continually extracted from the final effluent or treated sewage effluent, and passed through a flow-cell containing the sensors. The readings from these sensors demonstrate that wastewater treatment has been effective and that the treated water is suitable for discharge or in some cases re-use in irrigation, landscaping or industrial applications.

In order to prevent accumulation of debris in the flow-cell and to protect analytical equipment from suspended materials such as sediment and algae, it is common practice for this sample stream to pass through an inline filter/strainer. However, these filters can become blocked and this has a detrimental effect on the quality of monitoring; a blocked strainer can result in failure to detect a problem with the wastewater, so it is vital that regular maintenance ensures that blockages are minimised.

Debris dilemma

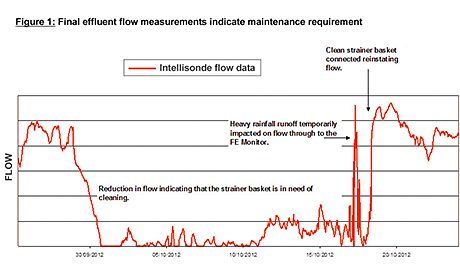

Unfortunately, the accumulation of debris is unpredictable and so routine maintenance cannot guarantee a free-flowing filter, so maintenance visits are inevitably more frequent than necessary, which represents an unnecessary cost.

The Intellisonde FE (Final Effluent) monitor provides continuous, long term, accurate monitoring of dissolved oxygen, conductivity, pH, ORP, ammonium, turbidity and temperature. The monitor’s sensors are solid state and require no recalibration once they have settled following installation. Furthermore, no membranes or chemicals are required and no maintenance is necessary until the sensor head is quickly and easily serviced; usually after 6 months. As a result, operational costs are considerably lower than alternatives that employ chemical/colorimetric analysis. Importantly, in order to provide access to live data, and for the Intellisonde to be able to issue an alarm, a built-in GPRS modem provides access to the monitoring data.

In addition to the parameters mentioned above, the Intellisonde FE also incorporates a flow sensor and an accumulation of debris in the strainer results in a lowering of flow rate which can be detected by the flow sensor. For unmanned sites the real-time monitoring of flow provides information to service engineers allowing them to prioritise/schedule their visits.

Explaining how the flow alarm is put into practice, Intellitect Water’s Jo Cooper says: “Ideally, the flow rate should not be allowed to drop below 0.1m/s, so we recommend that the alarm should be set at 0.2m/s or slightly above, to provide time to arrange a maintenance visit.