A RADICAL change of approach to grit removal in wastewater treatment plants, being introduced to the UK for the first time, could be fundamental to achieving progress towards water company TOTEX objectives in AMP6 and beyond, says supplier Hydro International.

Water companies open to the innovative principles of Advanced Grit ManagementTM (AGM) are expected to achieve significant operating and cost savings with a proven technology already successfully installed at some 200 operating plants in North America.

Hydro International is seeking water company partners to conduct pilot trials at wastewater plants in the UK, as well as to set up a full operating trial site. The trials will study the potential for AGM to establish new standards based on removing more, finer grit particles at the inlet works than has conventionally been accepted as standard. Already sampling studies underway with several water companies are showing promising results.

“The heavy cost of grit in wastewater treatment plant operation has long been accepted as an unavoidable burden by operators and asset managers alike,” says Keith Hutchings, Hydro International’s Group Product Manager. “Everyone knows that grit abrasion and accumulation are a burden of ongoing plant operation leading to heavy maintenance tasks and increased energy usage. Grit builds up in tanks, clogs basins and aeration tanks and compromises biological processes.

“The UK industry has accepted and grown to live with the burden of grit because of a compromise, a “one size fits all” industry standard for inlet works grit removal. With a new emphasis on TOTEX, we believe the time has come to challenge accepted norms. Grit sampling has never been conducted in the UK before and our sampling studies so far are providing strong evidence to support that view.”

The opportunity has come about through the technology transfer of a high-performance grit removal system to the UK from the USA. The HeadCell® grit separation system has been developed and refined during more than 30 years of operation. The HeadCell® is combined with the rigorous AGM approach to achieve optimum grit removal for each wastewater treatment plant.

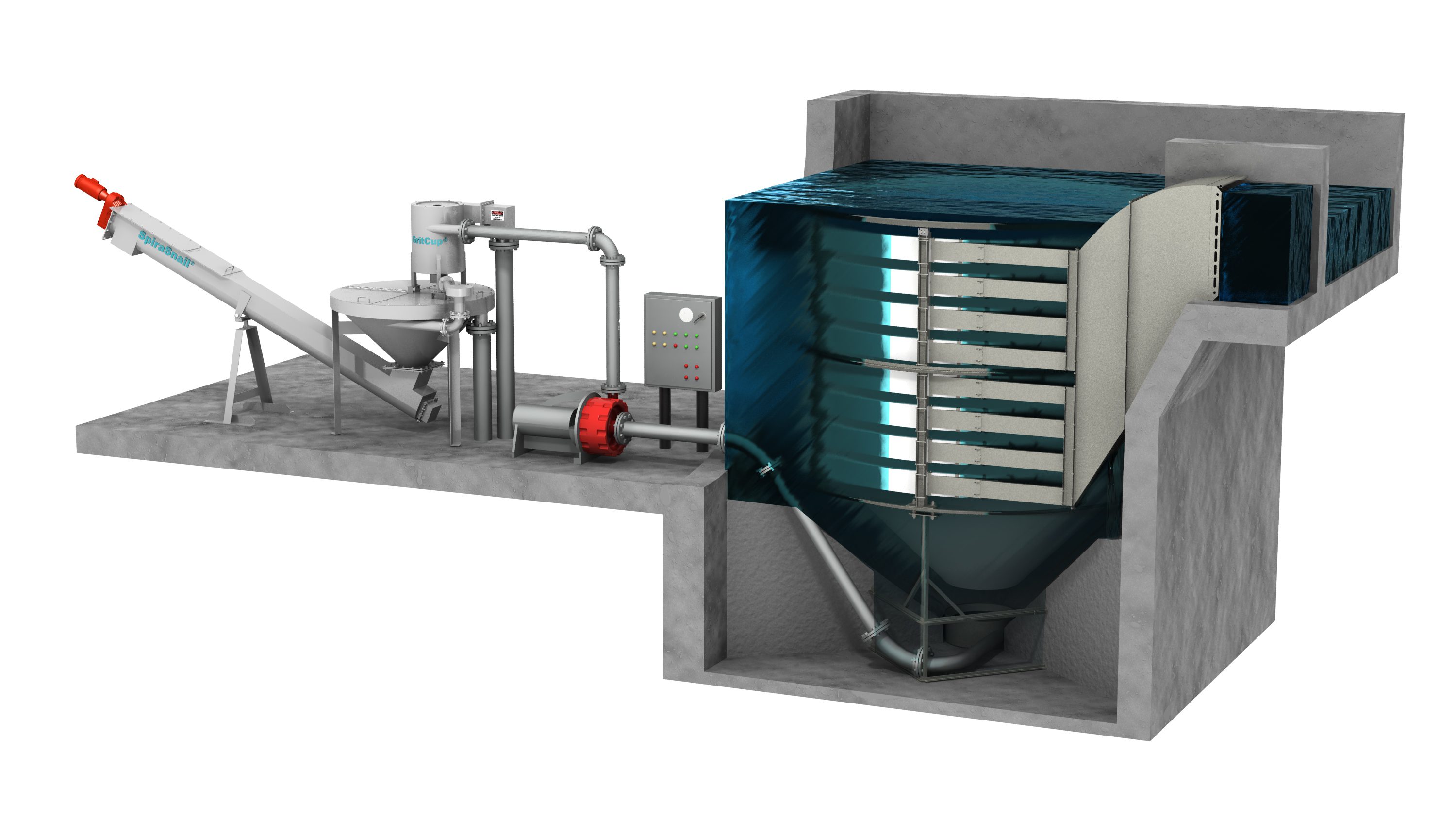

The HeadCell® is a high-performance solution for bulk grit removal both as an upgrade to existing plants and for new works. Capable of achieving 95% removal of all grit 75 microns and larger, the HeadCell® uses a stacked tray separation technique to create a large surface area with short settling distances capable of removing more fine particles. Its unique design means it does not suffer from the short-circuiting problems that reduce the efficiency of conventional grit basins.

A hydraulically-driven system with no moving parts, HeadCell® is modular and therefore offers a future-proof ability for upgrades. It delivers grit removal over a wide range of flows and with less than 300mm headloss in a much smaller footprint than conventional grit removal systems.

High-performance grit removal requires appropriate washing and dewatering systems that achieve the same performance. Without them, the finer grit would be washed back into the waste stream. As part of the Advanced Grit ManagementTM approach, Hydro recommends an integrated system to maximise grit removal performance. The HeadCell® can therefore be combined with Hydro’s GritCup® washer and classifier and SpiraSnail® dewatering system to achieve the best possible results.

For more information about Advanced Grit ManagementTM and Hydro grit removal technologies, call 01353 645700, email enquiries@hydro-int.com or visit http://www.hydro-int.com/uk/products/advanced-grit-management.