Merck Millipore, the Life Science division of Merck, has announced three additions to its MAS-100® family of air samplers. The MAS-100 Iso MH® and MAS-100 Iso NT® systems were developed for use in isolators and enable sampling at critical control points. The distinguishing feature of the MAS-100 Iso MH® system is its four sampling heads, which allow for increased monitoring capacity compared to single-head systems. The compact and easy-to-handle design of the MAS-100 VF® air sampler makes it well-suited for use in controlled environments.

Integrated design

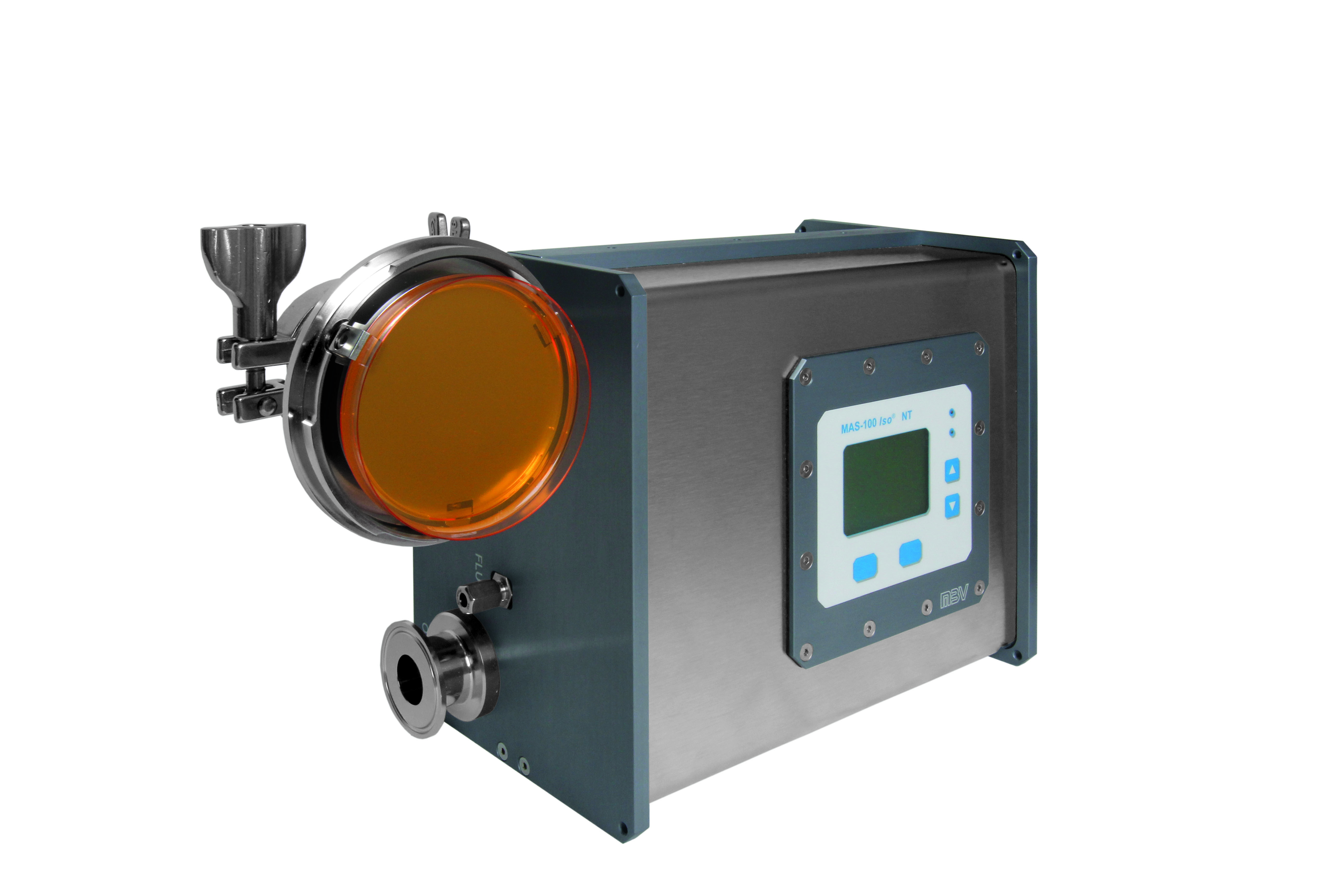

The MAS-100 Iso NT® system for monitoring air in isolators was developed according to GAMP 4 and ISO® 14698 standards. The fully validated air sampler contains an innovative double valve that integrates the sampling head into the decontamination process of the isolator. For added safety, electronic and moving parts remain outside the critical zone and an internal pump with flow control enables automatic disinfection of the sampling head and the aspiration tube.

The MAS-100 Iso MH® air sampler offers all the benefits of the MAS-100 Iso NT® and allows installation of up to four sampling heads at all critical control points. Multiple heads from one pump provide increased capacity, easier installation and lower cost than four equivalent single-head systems. Additionally, the system extends up to 10 meters in tube length, which facilitates use in larger isolators. The system was developed according to GAMP 5 and ISO® 14698 standards.

Easier to use?

The MAS-100 VF® active air sampler was validated and developed for air monitoring in controlled environments. The system’s compact design allows for ease of operation, says Merck Millipore, and its added handle can be mounted on a tripod to test different angles for fixed applications. Electronic speed control ensures a consistent and accurate flow rate, and a touch-slide control menu enables simple menu navigation. The system programs sample volumes from 1 to 1,000 liters with five presets to assure reproducible results.

Monitoring air in controlled environments

“Air contamination in manufacturing facilities can impact product quality and increase risk to consumers,” notes John Sweeney, head of Lab Solutions Business, Merck Millipore. “It is therefore essential to implement robust and accurate microbiological monitoring of air in all manufacturing areas. With the MAS-100® product family, Merck Millipore offers its customers the broadest portfolio of the most accurate microbial air monitoring systems on the market, enabling manufacturers to ensure the highest quality products and increased consumer safety.”

The MAS-100® family includes systems for testing air and compressed gases in cleanrooms, aseptic production areas, isolators, and other controlled environments. MAS-100® microbial air samplers comply with the guidelines as specified in the new ISO® 14698 part 1 and part 2 standards.