“When we took the first look at the Landia pumps, our first response was to laugh,” said Joe Freyer, Maintenance Supervisor at the Fourche Creek Wastewater Treatment Facility (FCTF) in Little Rock, Arkansas. The pumps were small and did not resemble the big cast iron units they were used to.

Freyer and his team were concerned the new pumps would not perform well. However, he says, those small pumps would go on to make a big impact and prove a wise investment.

The apparent success of FCTF is attributed by Freyer to the work that goes into it. “We constantly check everything throughout the facility to ensure we are in good shape,” he said. “It’s an aggressive schedule but we thrive on it. We don’t wait until something breaks. Our software is designed to notify us and integrate with our preventative maintenance program. For example, oil levels are checked once a month on our submersible pumps and we also inspect the Impellers, once every year. In the meantime we conduct visual checks – and we have a good ear too, and can detect when something doesn’t sound quite right with the equipment.”

This proactive approach, which encompasses 28 pump stations and three treatment facilities, seems to help avoid drastic repair bills and is said to have virtually eliminated downtime. More importantly, it ensures Little Rock Wastewater achieves its stringent discharge permit.

Serving a population of 183,000, the Fourche Creek Treatment Facility FCTF (43 MGD), the Adams Field Treatment Facility AFTF (72 MGD), and the Little Maumelle Treatment Facility LMTF (5-14 MGD), are all closely monitored by state and federal entities.

Processes at FCTF

Although required to reduce pollutant loads by 85 percent, FCTF consistently achieves 90-95 percent removal through its physical and biological processes, according to Landia’s press release. An innovative secondary treatment facility with a step-feed activated sludge process, FCTF receives wastewater from southwest Little Rock via pressure lines from the College Station & Arch Street Pump Stations. FCTF also receives solids through a 5-mile Force Main from AFTF, which is a complete mix activated sludge facility.

Here, flow to the activated sludge secondary process goes through six rectangular aeration tanks, where a biological microorganism population utilizes the incoming dissolved organic material in the wastewater as food. The biological organisms settle out in the secondary (final) clarifiers and are returned to the activated sludge aeration tanks to maintain a viable microorganism population.

Sludge from both AFTF and FCTF is combined and then thickened at FCTC, prior to being introduced to one of four 1.2 million gallon primary anaerobic digestion tanks. Here it is held for approximately 30 days, at a constant 95°F (35ºC), and free of oxygen, obviously. The methane gas is collected and piped to the generator building where it is used as an alternative fuel source to provide up to 100% of the facility’s power, saving FCTF three quarters of a million dollars annually (over $2,000 per day). Approximately 1150 kW of power is produced, with around 850 kW for facility load and approximately 300 kW of that is put back on the grid.

Where the pumps are used

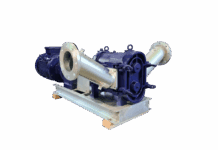

The Landia Pumps that prompted an initial chuckle from Joe and his team were introduced eight years ago to pump the AD solids. They replaced a different manufacturers screw impeller pumps, which had been failing mechanically. On the pedestals where the previous pumps sat, the Landia Model MPTK close-coupled Chopper Pumps take up only a third of the space.

“I have to admit, we have a little egg on our face,” admits Joe. “Those Landia pumps have performed very well and continue to do so. They are tough machines and they have to deal with whatever gets through the bar screen at the headworks. Primarily we take in domestic wastewater and get a lot of rags. We are also in a major rice-producing area, which means we receive some pretty tough effluent and with a pH of just 3, it needs chemical treatment before it enters the digesters.”

Apart from typical preventative maintenance, there apparently has been very little in the way of repairs required over the 8 years the pumps have been in use at FCTF. Those repairs were one rewind, two mechanical seals and a cutter.

“Previously, with our old screw impeller pumps we had to take them offline and remove them to clear the debris, which caused considerable downtime, but the Landia chopper pumps are far better at chopping the debris. They just keep running, which is a great track record considering some of the pumps run 24/7. We still have the original impellers on them.”

In addition to the Landia pumps, there are also half a dozen Landia mixers installed throughout the Little Rock Wastewater treatment foot print.