By Keith Hutchings of Hydro International

WHEN it comes to grit, do UK water companies know what they are missing? Grit is the scourge of a wastewater treatment plant and, with Totex objectives high on the agenda, the good news is asset managers, operators and maintenance engineers no longer have to “put up and shut up” about grit.

Yet all too often, effective grit removal is neglected or overlooked. Our research shows, on average, 60% of all grit could be being missed by existing conventional solutions – a major source of avoidable process inefficiency and operating, maintenance and replacement costs.

Too often, the costs are borne as part of ongoing plant operation – almost without question. Whether a primary tank or digester needs cleaning out, a sludge pump stripping down, or aerators need unclogging, it is just something that has to be done.

Our experience of working with wastewater treatment plants around the world has taught us that operators are settling for very low percentage rates of grit removal efficiency – typically removing only 30-50% of incoming grit.

Now, our attitudes to grit are changing and the realisation of the true cost of grit – especially finer grit- has started to undermine this stance. At Hydro we have even developed a Cost of Grit Calculator as an online resource.

Why grit matters

Grit threatens effective treatment through abrasion and accumulation; poor grit removal leads to process inefficiencies and increases electricity costs.

Grit:

• accumulates in channels, pipes, primary tanks, digesters

• wears out pumps, valves and other mechanical equipment

• blinds filters and membranes

• clogs aeration basins and diffusers

• disrupts biological processes

• reduces the effectiveness of energy recovery

• reduces the quality of final effluent with a risk of exceeding pollutant limits

The grit shake-up

We believe that the standard industry model for grit removal that has been taken for granted for more than 70 years is wrong. Our current industry standards (WIMES standard no. 2.02 Grit Removal and Treatment Equipment 2008) make assumptions about the nature and form of grit. Similar to the current USA standards (Water Environment Federation Method of Practice 8 and Metcalf and Eddy) they make some key assumptions for ‘convenience’, including the following:

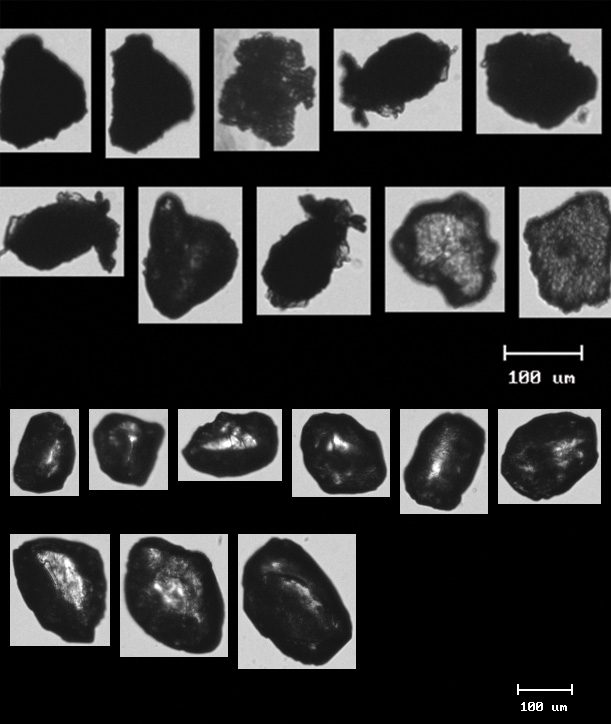

• Grit is a clean silicate sand particle of above 200µm in size

• The particle has a uniform, smooth spherical shape

• The specific gravity (SG) is 2.65.

Based on these assumptions, the standards have established an all-purpose particle settling-out rate depending on flow rate, which defines conventional treatment and equipment design parameters. Conventional grit removal equipment is designed to remove up to 95% of this size and shape of grit. That is – if working at peak design efficiency.

Are we looking at the wrong grit?

The trouble is, the sampling we are conducting at a number of plants in the UK is consistently showing that this cosy picture of grit is wrong. Overall, we are finding that around 60% of grit is smaller than 200 µm and in some places an even greater proportion than that. The indication is that most grit removal systems may actually be removing as little as 20% to 30% of the incoming total grit load.

From our experience working with more than 200 installations in North America we know that, in fact, the majority of particles can be in the 106 µm to 75 µm range, or even smaller. Grit shapes are seldom spherical and shape significantly affects the particle settling rate. Actual particles are frequently rough in texture, which allows even smaller particles and organics to bind to them.

The particles frequently carry organics, such as soaps, fats, oils and grease, which expand the surface area or clump together, and thus significantly affect the settling rate.

Conventional equipment is designed around notional rapid settling rates seldom actually seen in raw wastewater, so does not trap slower settling particles, i.e. the smaller and larger, non-round, low density particles that form the majority of the grit intake. False assumptions about grit are exacerbated by standard industry inlet channel sampling techniques that sample from the bottom of the channel, rather than from across the whole channel depth.

Profiling grit

In the USA there is growing acceptance and support for grit removal techniques that are able to remove grit particles 75 µm and larger. They focus on methods to remove the 106 µm to 75 µm grit particles, depending on the needs of the plant, while at the same time also removing larger particles above 106 µm.

Behind the successful deployment of these techniques is an approach which Hydro calls Advanced Grit Management™ (AGM).

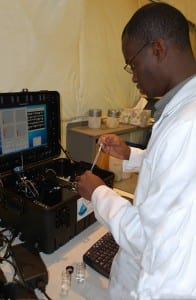

The basis of AGM is sampling inlet waters to gain an accurate profile of the incoming grit, and then recommending and tailoring a combination of technologies to meet those conditions for an individual plant.

The premium collection technology uses a stacked tray design called HeadCell® which uses a large surface area and short settling distances to capture fine particles. HeadCell® achieves up to 95% removal of all grit 75 µm or larger.

To guarantee these levels of performance, HeadCell® is accompanied by washing and dewatering technology, so that all organics are effectively removed while preventing smaller particles being resuspended. GritCup® washer and classifier and SpiraSnail® dewatering units have been developed for integration with HeadCell®.

An alternative solution designed as freestanding unit or where headloss is tight, is the Grit King® advanced hydrodynamic vortex flow grit separator, which has no moving parts or power uptake. It can achieve up to 15 times better grit removal than conventional systems and is highly versatile.

Find out what your plant is missing

The effects of high-performance grit collection on the typical wastewater treatment plant operation vary from plant to plant, but are usually considerable and can be calculated for every plant. Hydro International is currently undertaking sampling at WWTPs across the UK and has a pilot unit available to install on site free of charge.

Hydro is also discussing opportunities with UK water companies to partner a full equipment trial for a HeadCell® system. With innovation high on the agenda, it looks like grit could turn out to be an unlikely game changer for the UK water industry.