Envirotec listened in on a presentation by Matthew Callan of Ardent Marine Services, at an event held by IESIS in January 2016, explaining how his firm approached the salvage of the Costa Concordia, completed in 2014 and said to be the largest wreck removal operation ever undertaken. It was also one guided by the constraints of working within a fragile marine ecosystem.

Fuel removal is the most immediate priority with accidents of this kind, and in this case it commenced within 15 hours. This was the morning after the evening of 14 January 2012, when the Costa Concordia had run aground and rolled onto its side, coming to rest on a rocky shelf near the shore of the island of Giglio on the Adriatic coast of Italy. As Callan recounts, his own firm were present on the morning in question, along with other international salvage experts, although the contract for the fuel removal operation went to a rival.

Ardent stayed on site for four weeks to prepare commercial documents to tender for the main salvage contract, for the removal of the wreck. He said: “It was clear very quickly this was not going to be a simple refloat-and-move-off job”. Eventually they were awarded the contract, along with Italian marine EPC contractor Micoperi, and the operation could begin, the ambition of which was clear from the outset.

Deep water dumping not an option

Seemingly the usual scenario following a shipwreck of this kind is to simply cut up the vessel – often using a combination of chain and wire cutting – and tow the various pieces away for disposal in deeper water. In this case the vessel’s location – in a national marine park in the Mediterranean – and the fact that it was a floating hotel, filled with luggage, consumer items, food stores and so on, meant this option had to be ruled out on environmental grounds.

The precariousness of the operation, the eye-watering costs involved (between €1.2B and €1.5B to the insurers, at the final estimate), the serious implications for the ecology and economy of the local area, and the fact that no one had ever attempted to move such a large vessel (bigger than the Titanic at 112k metric tonnes), lent the whole project a dimension of heroism and spectacle that is captured well on the Discovery channel documentary Inside Raising the Concordia (recently made available on youtube).

Given the ship’s situation, sitting on a 35 degree slope, which within twenty metres or so fell away into much deeper water, there was great concern from the outset that strong waves could dislodge her, making salvage virtually impossible. So one of the first tasks was to secure the ship to the rocks. And this was accomplished by fixing anchor blocks to the rocks, from which ran high strength cables, attaching to the hull (see image, below).

The holdback arrangement looked like it was going to require around six kilometres of Dyma steel cable – a not inexpensive proposition – but various engineering concepts were explored to help minimise this requirement. Eleven anchor blocks were secured to the rocks, weighing around 1000 tonnes each.

Drilling challenges

The securing and other operations undertaken during the salvage required large amounts of underwater drilling, one of the most challenging aspects of the project, suggested Callan. Picture a scenario where divers are required to operate 80kg drills, trying to penetrate a granite surface that is inclined, making it impossible to drill vertically, and you get a clue as to the difficulty. Callan suggested the team greatly underestimated the amount of time it would take to drill into granite, an operation that was running against the clock given the urgency of proceeding before any bad weather could come in. The whole salvage operation called on the assistance of around 130 certified divers, logging in the region of 15k individual dives.

The vexed question of what to do in the event of bad weather apparently inspired a lot of brainstorming, one of the more off-the-wall possibilities being to park a very large crude carrier (VLCC) in front of the sunken vessel to act as a breakwater (an expensive one).

Initial surveys

In the early stages of the operation Ardent worked with a specialist in subsea laser scanning, to gain a better understanding of exactly how the vessel was sitting on the rocky outcrop. The resulting information was mapped onto a detailed topography of the seabed.

One of the technical challenges that quickly became apparent was the fragility of the structure, owing to the fact that it contained so much open space (shopping malls, theatres and so on). There were also geotechnical issues to be explored in relation to how the ship ought to be rigged to carry out the parbuckling operation.

“This was always going to be a two- or three-year job,” said Callan.

There were also numerous surveys conducted to better understand the condition of the surrounding environment, for the benefit of the Italian government, who wanted to make sure that “when the wreck was cleared we also spent a lot of time returning the environment to the way it was before”.

The political issues around salvage can be enormous, and this one appeared to be no exception, given the circumstances of the accident, with its Italian captain and its location within an Italian national marine park. “There were a lot of stakeholders with a lot of influence and a lot of oversight into what we were doing – it needed constantly careful management.”

However, he said they were lucky with the amount of leeway they were afforded by the ship owners and the insurers – they had the opportunity to be innovative and creative. When a national government has close oversight over a project, this kind of freedom is unusual.

The firm performed numerous surveys to guide the environmental protection element of the project, including a detailed cartography of the area and the ship to evaluate the various benthic communities and how they might be affected by the operations to be carried out. “We seemed to spend time learning an awful lot about some very obscure things,” said Callan. The marine park houses a variety of large mussels, pinna nobilis, which are exceptionally rare and specific to this location. The salvage team had to remove them to another location for safekeeping, by hand, then move them all back again (see image, below).

Coming at it from an angle

With the ship being inclined at 45 degrees, it was a challenge getting your head around the orientation of what you were doing, said Callan, even above the water, where workspaces, welding workshops and so on had to be arranged at this odd angle. As for the difficulties this presented underwater – Callan simply laughed at the recollection of his own attempts at this kind of diving.

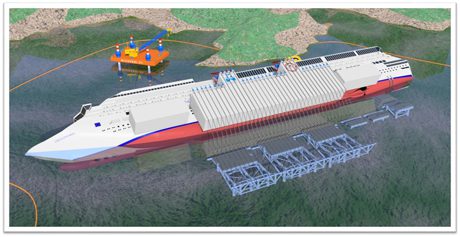

Once the hull had been secured to the rocks, the next steps were to build horizontal underwater platforms below the ship, then attach airtight tanks (or ‘sponsons’) to the side of the vessel, and bring the hull into an upright position by winching (or ‘parbuckling’ as the procedure is called) onto the platform.

The undersea platform was built on rocks 100 feet deep, the securing of which presented further challenges for the diving crew, although this work also relied on the use of remotely-operated underwater vehicles (ROVs) equipped with cameras. Around 27k hours of ROV footage were taken during the project, which meant “a lot of guys got very good with the PlayStation controllers”.

Attaching buoyancy

The next step was to attach sponsons to the port side of the hull, in preparation for attempting to refloat the vessel. These were enormous airtight cubes, each roughly three stories in height (though there were two sizes, one slightly smaller than the other) and weighing 400 metric tonnes. Around 30 of these were attached to the vessel, 15 on each side. Eleven of these were installed before parbuckling, and the rest afterwards. The construction of these cubes made up a large share of the work carried out by Micoperi, the Italian contractor who partnered with Ardent on the project.

The attachment of the these huge buoyancy tanks required a lot of heavy lifting work, a first for the various support vessels used in salvage work. The tolerances present here were also a challenge, given the state of the vessel, and the size of what was being lifted, and the odd angle of the vessel onto which the sponsons were to be attached – a 48 mil separation was required between each of the sponsons.

Firms like Callan’s tend not to own this kind of floating plant, so a large workload is involved in getting hold of it from ship owners and so on, subcontracting equipment as and when it’s required. The suppliers are often none too keen either, when they hear it’s for salvage work, which has a reputed tendency to bang things around. But this time Ardent found a ship owner who had worked with them before, who was “very helpful”.

More than a bit of grouting

The platforms onto which the ship was to be lifted also required a lot of grouting (“the largest grouting operation we’ve ever undertaken”), all of which had to be done manually by divers, taking grouting bags down to the sea bed and laying down grouting products, working within tight tolerances of around 5 to 10 mil. “It was a hell of a task filling these things up then getting them down to the sea bed.” These platforms were fabricated in the Micoperi yard and then had to be put in place, requiring a lot of drilling, using gargantuan 2m-wide drill heads – although the resultant holes appear no less clean and precise for that, as the image below shows. The subsea drilling templates were themselves also substantial in size – around 290m long.

Salvage is all about adapting to changing circumstances, it seems, and one fairly large unforeseen factor with the Costa Concordia operation, whose consequences were not fully appraised until four or five months in, was the instability of the section of the hull around the bow, around 80m of which appeared to offer insufficient support to allow the parbuckling operation to be carried out. “As we started doing the finite element analysis, we became very concerned that [ an undesirable ] scenario would happen, which is that the bow would break off.”

To stabilise the bow section, the team decided to use blister tanks – cubes of buoyancy about four or five stories high – which were assembled around the bow section to provide a kind of “neck brace”.

Software-controlled buoyancy

The parbuckling operation required very fine control, effected by ballast control systems attached to the sponsons, to manage the buoyancy levels in different parts of the vessel – there were 66 of these in total and they required “pages and pages of software code” to run, to control the buoyancy levels appropriately. Running in tandem with these buoyancy units was a system of strandjacks, providing heavy lifting (around 9000 tonnes of force was available on site). All of this was overseen by the salvage master, Nick Sloan, situated in a nerve centre receiving multiple live feeds from around the wreck.

Around 6800 tonnes were going to be required to pull the ship round and break her free of the rocks by about 3 degrees. “When it got past 5000 and up to 6000 people were getting very nervous,” recalls Callan. The nerve-shredding continued until the 6800 level was reached and the ship broke free – to widespread relief. The whole operation took around an hour, and once the ship reached 35 degrees there was a controlled flood of the sponsons, and gravity did the rest.

Preparing for the scrapyard

Once righted, most of the vessel remained underwater, but it was possible to assess the damage – as the image above shows, there was a visible “push up” area of damage where she had lain on the rocks. But on the whole the vessel had held up “incredibly well”, said Callan, having lain for 22 months – three winters – in Giglio.

The next stage was to transport the vessel to Genoa where she was to be scrapped. Like the rest of the project, this stage also proceeded under the watchful supervision of the Italian government, with six escort vessels in close proximity and a team of around 52 people, including 10 marine biologists – with some in front, and some behind, taking measurements of the water to make sure there was no debris coming off the boat.

For the dismantling operation, the vessel was handed over to an Italian consortium.

As one audience questioner remarked, you don’t get much of an opportunity to prepare for a unique project of this kind, so it must have involved an element of “flying by the seat of your pants”. Were there sleepless nights for those involved? Callan said only two or three salvage specialists in the world have the capability for this kind of project, and indeed “nothing of this scale had ever been attempted before”. In terms of novelty and technological sophistication, it was the ballast control software that “really blew my mind”, he said. He admitted to only one or two sleepless nights, but the senior salvage master, Nick Sloan, had lots of them. As the central focus of the whole project, he had something like four or five days off in the near two-year period of the operation.

For information on other events organised by IESIS follow this link. The above event was organised by IESIS, IMarEST, IMechE, RINA and WES.