Lührfilter has recently commissioned a flue gas treatment system for Mastermelt Refining Services, based in Derbyshire. The system currently treats the flue gases from 3 off industrial incinerators which treat specialist scrap to remove precious metals. The system has been designed with the capability for additional incinerators to be added in the future.

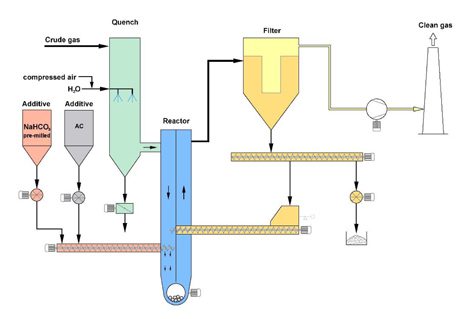

The Lührfilter scope of supply included the design, manufacture, installation and commissioning of a complete system to treat the waste gases from the incinerators in terms of temperature control, dust collection and the removal of acid gases, heavy metals and dioxins. The temperature control is enabled by an evaporative “quench” tower, which injects atomised water into the gas flow and automatically controls the temperature reduction from approximately 900OC to < 180OC. The hot gases are transferred to the quench system by a specially designed refractory lined and stainless steel duct system, which includes automated flow control dampers.

Once the gases have been reduced to a suitable temperature from the quench tower, they enter a reaction chamber fitted with a patented Lühr conditioning rotor. At this stage, the waste gases are mixed with 2 additives are controlled and metered into the system. The additives on this plant being Sodium Bicarbonate and Activated Carbon. The Sodium Bicarbonate removes acidic content from within the waste gas (such as SO2, HCl and HF), whereas the Activated Carbon removes heavy metals such as Mercury and Dioxins. The quantities of each additive fed into the system are controlled by a “recipe” system, where the incinerator operator identifies the scrap type in each incinerator and the system automatically calculates the quantity of each additive required to neutralise the contaminants in the specific scrap. The conditioning rotor then ensures the maximum level of interaction between the waste gases and the additives. See Figure 1 below.

Once the waste gases have passed through the reaction chamber, they enter the bag filter plant which removes the additive and particulate from the waste gases. These are separated from the waste gas using high efficiency, high temperature filter bags. The filter bags are cleaned using pulses of compressed air, which are directed into the clean side of the bags and shock the dust cakes from the outer surface. The particulate then falls into the dust collection hopper.

The complete filter plant is thermally insulated, with the dust collection hopper and certain other key components electrically trace heated, which prevents the build-up of condensation within the plant, especially when it is off-line.

Once the mixture of ash from the incineration plant and the residue additives fall into the dust collection hopper, although a small quantity is discharged into a collection vessel, the majority is recycled back into the reaction tower, where it is again utilised to remove contaminants within the waste gas. This is because not all of the surface area of the additives are used on a “single pass” system. By recycling the additives (combined with ash residue) a greater percentage of the surface area is utilised and also reduces the plant operating costs, as less virgin additive is required.

The system is completely automated with a custom built and designed control panel, this monitors all parameters, including the pressure at the incinerators, inlet and outlet temperatures, the differential pressure across the filter plant and particulate emissions. In addition, the control panel controls the incinerator operation, the water/ air injection into the quench tower, the additive dosing rate based on type of scrap in the incinerator, the filter cleaning system and controls the fan speed via a frequency inverter.

A local control panel was also installed at each key component part of the plant (including each incinerator), which allows an over-view of the complete system with a HMI, together with local control functions.

Additional safety features are designed into the system, including a safety fresh air dilution damper, which prevents over temperature for the filter bags. There is also a by-pass system integrated into the system which activates in the event of power failures.

This high specification fully automated system allows Mastermelt Refining Services to process a broader range of scrap, with greater control and increased throughput times, says Luhrfilter. The system ensures that the flue gas treatment system and the incineration process can be fully monitored at all times from various locations. The flexibility also allows the integration of additional incinerators in the future.