A seemingly revolutionary approach to offshore wind turbine installation and maintenance could cut the cost of energy from future deepwater sites by around 9%.

The results of a £200,000 Innovate UK Energy Catalyst study involving detailed engineering analysis on the Self Erecting Nacelle System (SENSE) show the new technology could also trim 4% from the cost of energy at current wind farms in relatively shallow water.

There is currently no proven technology capable of installing the next generation of turbines and towers on foundations in water depths greater than 60m apart from building ever larger and more expensive jack-ups and semi-subs.

SENSE Offshore Limited, which is developing the technology for commercial roll out in 2021, says its system means large jack-ups and crane vessels are not needed to install the turbine nacelle and rotor or for maintenance including the change out of major components.

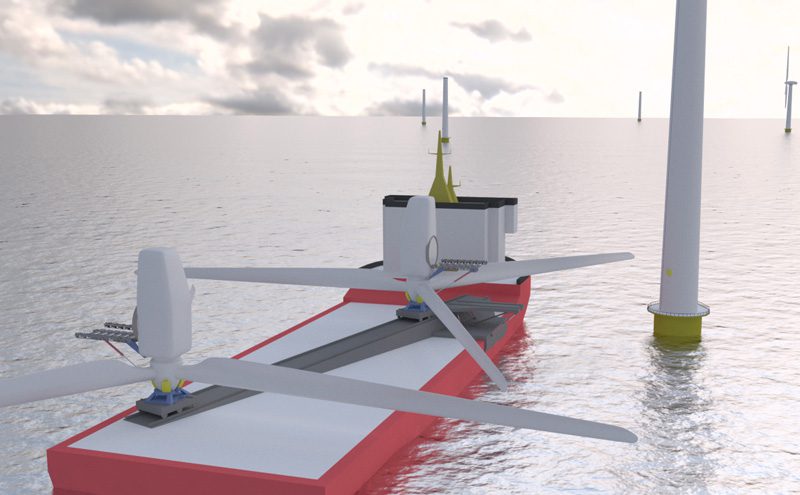

SENSE is a modular, removeable transport and installation system mounted on a standard large construction vessel.

SENSE Offshore MD Patrick Geraets says: “Wind turbines are getting bigger and developers want to exploit deep water sites. How are these turbines going to be installed? SENSE is an answer – faster, cheaper, independent of water depth, with world wide application and it is scalable to the larger turbines coming to market in the next five years.”

SENSE transports a pre-assembled and tested rotor nacelle assembly on board a large multi-purpose construction vessel and has solved the problem of transferring 700+tonne loads in significant wave heights from the vessel to the tower. The SENSE transportation carriage then carries the turbine to the top of the tower on rails. The process is reversible for maintenance and replacement.

The Innovate UK Study was carried out for SENSE Offshore by a project team of leading contractors including GBG, PHG Consulting, Industrial Systems and Control, BVG Associates, Knowtra and James Fisher Marine Services.

It found the SENSE System could cut around €125m from the capital expenditure (CapEx) on a €5.1bn, 1200MW wind farm in waters in excess of 70 metres and save €28.5m a year in operating expenditure (OpEx). On a shallower large site where water depths are similar to North Sea farms currently being built with jack-ups, SENSE could save €84m in CapEx and €10m in OpEx per year.

SENSE Offshore is now planning the next stage of development to bring its technology to market within 4 years. Geraets says: “To do this we need to significantly accelerate the pace of development, for which we need both investment and industrial partners.”

The company is looking for partners and investment to add to an Innovate UK Energy Catalyst application that is currently under way for an award of up to £1.5m. This project will carry out detailed design and engineering and onshore scale tests to demonstrate the SENSE System in preparation for undertaking a full-scale test offshore.

“A partner or investor could be an existing construction company looking to expand its offering to the offshore wind industry to include large turbine installation and maintenance, or a new entry eyeing this growing and substantial market,” says Geraets.