Ham Baker has completed the installation of new precision-engineered penstocks at the Rosyth, Fife site of engineering support services firm Babcock.

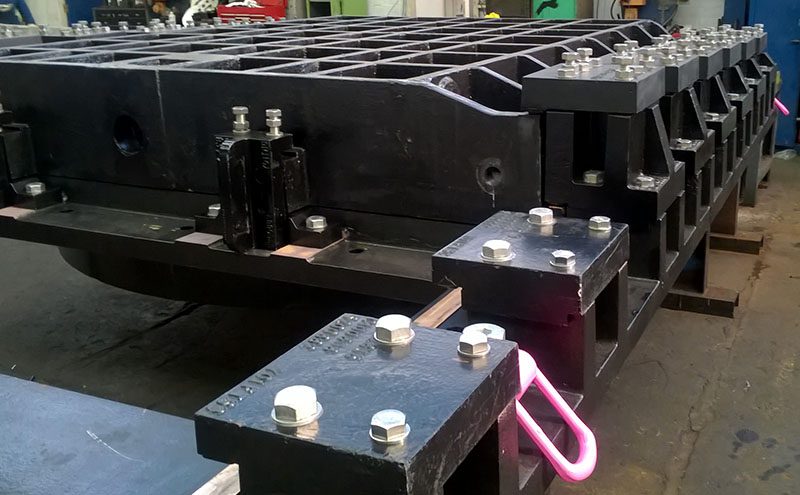

Working closely with Babcock, Ham Baker was appointed main contractor for the design, manufacture and installation of four 11.5 ton (each), 2.4m sq penstocks. The firm was also responsible for new hydraulic actuators and support steel work, in addition to new control kiosks, platforms and ladders.

Completed ahead of schedule and within budget, Ham Baker first had to remove the old penstocks at Rosyth, which had come to the end of their life. Working at a depth of 14m in confined spaces next to the water’s edge at the Firth of Forth, Ham Baker had to adhere to exacting health and safety standards.

Ian Donnelly, Babcock’s Managing Director of the Rosyth site, said: “This was a demanding project, requiring experience and good engineering skills. From start to finish – despite the tight programme – Ham Baker completed the work without any issues.”

Mick Evans, Senior Projects Manager at Ham Baker, added: “This was a tough test at the site’s entrance lock, not helped by delays due to high winds when we couldn’t use cranes, but our specialist team were extremely determined. After first installing the new penstocks down at 14m, we gradually worked our way back up by putting in new ladders and platforms, support steel work and then, finally, the actuators and the new control kiosks.”

At Ham Baker’s headquarters in Stoke-on-Trent, where everything for the penstocks and ancillary equipment was manufactured, 3D modelling was utilised and an extensive Finite Element Analysis (FEA) conducted to ascertain the penstocks’ capability against pressure, and physical effects.

Ham Baker also advised on hydraulics, pre-tested actuators and subjected castings and anchor bolts to rigorous strength evaluations.

The new penstocks – a five-month site project – were made with special tungsten carbide seals to prevent erosion and galling, where standard materials can fuse together through pressure and wear. The use of tungsten carbide also ensures that the surface finish does not deteriorate, even after years of operation.

Ham Baker is also currently working with Babcock on the refurbishment of further existing penstocks at the Rosyth site through their Spares and Maintenance division, also based at the Stoke-on-Trent headquarters.