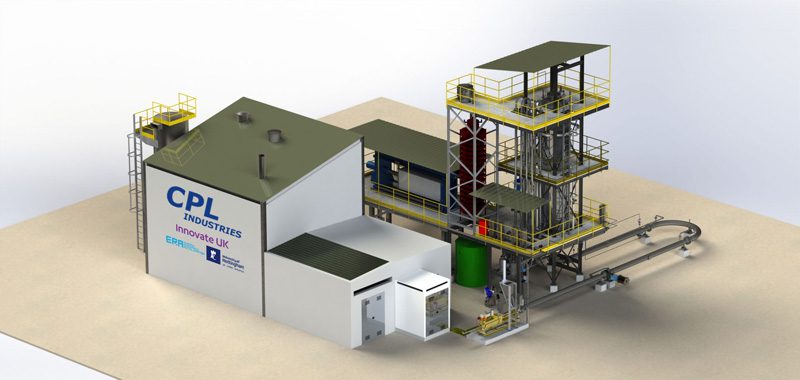

CPL Industries, a manufacturer of smokeless fuels and other carbon‐based products, has recently announced plans to install a commercial‐scale Hydothermal Carbonisation (HTC) facility at its production site in Immingham, North Lincolnshire. This will seemingly be the first commercial‐scale example of the technology anywhere in the UK.

Scheduled to begin production in mid‐2018, it is being developed by CPL’s Spanish partner Ingelia.

The new facility is being constructed in partnership with the University of Nottingham (UoN) and The Energy Research Accelerator (ERA), an initiative funded by Innovate UK that works with universities and industry to support research and innovation in energy.

What is HTC?

HTC is a technology for converting high‐moisture biomass into solid fuels using moderate temperatures and high pressures. The HTC process effectively mimics the long‐term natural process of coal formation, with the process taking a matter of hours rather than millennia. The process is able to process waste streams such as green / organic waste into value‐added fuel products that could be used in both domestic and industrial applications.

CPL and the UoN are looking for partners to supply waste material to the plant and collaborate on future commercial projects.

CPL’s intention for the HTC facility, which will form part of the company’s ‘Ecofuels & Carbon Technology Park’, is to investigate suitable replacements for fossil fuels in its home heating products, with possible future developments being the possible replacement+ of coking coals in industrial applications such as foundries and smelters.

CPL Industries has an ongoing programme for the development of next‐generation fuels based on biomass materials and novel production processes, and already has products on the market containing biomass material, including Homefire Ecoal 50, containing 50% renewable material, Homefire Olive Briquettes and Super‐Charged Heatlogs.