Bio-waste handling and processing firm Tidy Planet is bringing to the UK market an Artificial Vision System (AVS) for boilers – described as “the latest waste-to-energy boiler technology”.

The news of the Macclesfield-based firm’s partnership with Valencia-headquartered energy generation expert Sugimat was announced earlier in the year. And Sugimat’s new AVS made its inaugural appearance at Valencia’s FIMMA-Maderalia fair in February.

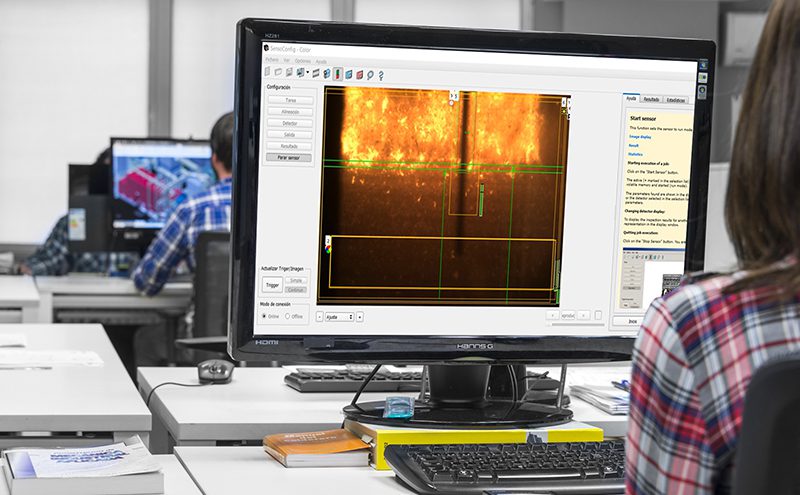

The “intuitive camera-driven equipment” is located in the biomass system and continuously monitors the fire in the boiler by observing the flame – to regulate air flow, grate movement and fuel feed – enhancing the environment for maximum heat output and fuel efficiency, as well as reduced emissions.

It has been designed and engineered to significantly improve and optimise the combustion process – a similar technology to what is used in automotive firm TESLA’s newly developed heaters.

James Tyler, director at Tidy Planet commented: “With an accelerated industry demand for biomass boilers, technology that not only monitors but optimises combustion conditions, enables organisations to reap a wealth of benefits – especially where the use of variable feedstocks and reduced operator costs are concerned.

“For example, the AVS’s constant boiler supervision and regulation works to improve the efficiency of non-homogeneous fuels by up to 10% – as well as incrementally reducing emissions and the need for human intervention. As a result, this enables companies to generate more energy, reduce labour and eliminate any wastage from the fuel that they are putting in – which are obvious environmental and financial advantages.”

The technology can not only be retrofitted to Sugimat’s range of boilers but can also be added onto other boiler brands. This enables sites with troublesome fuels – where clean and efficient combustion is difficult to achieve – the opportunity to experience the same significant benefits.

Sugimat’s business development director Alex Mas added: “The computerised AVS is smart and self-sufficient, using real-world image-processing tech to act as a human eye during the combustion process.

“As the equipment can anticipate, localise and rectify potential faults, less human interaction is required for maintenance – increasing both the machine’s up-time and a business’s bottom line.”

Having first worked together in 2016 on the DHL-Gatwick Airport Energy-from-Waste plant project – when the Airport became the world’s first to process CAT1 International Catering Waste on-site – Tidy Planet and Sugimat say they are both committed to harnessing waste as a valuable resource.