We know water is an increasingly scarce resource. So, what can businesses do to improve the way that water is used, treated, recycled and disposed of in a more sustainable way? And is it possible to save money achieving this? Keith Hutchings, Europe Product Manager at Hydro International explained the financial burden that water treatment can put on businesses: “Since 2010, fines for unpermitted discharge of water and pollution have cost businesses £45.9 million. Whether you process vegetables, brew beer, or recycle paper, you can’t just pour your water down the drain. The dirtier the wastewater, the more money you pay.”

Industrial organisations may need to source and treat water for many uses throughout a manufacturing process. Whether this be through potable water supply from the local water company or abstraction from a river or canal, this water supply may require additional treatment to be of the necessary standard.

Discharging wastewater to local water companies is becoming more restrictive, and licenses harder to come by. Add to this the fact that that water supplies are literally drying up, and the ability to be able to recycle and reuse wastewater or treat it before discharge is a financially sound move for business.

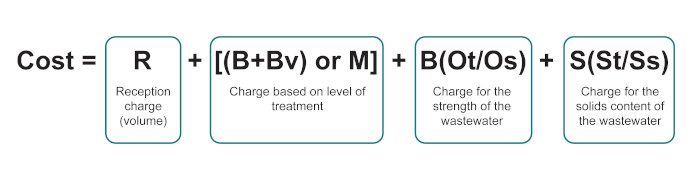

Water companies use a very specific formula to calculate the cost to businesses when they discharge trade effluent to a sewer. This is known as the Mogden Formula. The formula (shown below) has four elements, and the costs associated with each element can be decreased by treating or recycling water on site.

Reception – the volume of wastewater you discharge

Level of treatment at the works – this could be a discharge straight to the sea or may need to run the wastewater through primary, secondary or tertiary treatment process.

Chemical Oxygen Demand (COD) of the wastewater – this charge is based on the ratio of what you are discharging over the average discharge of a municipal customer of the local water company.

Solids Content – this charge is also based on the ratio of what you are discharging over the average municipal customer of that water company.

Screens and washers can treat raw water, removing all kinds of solids. There are also a range of conveyors that can gather and move the solids. These solids can also be pressed and dried, potentially giving the opportunity to produce energy from waste.

Keith continued, “To reduce the volume charge, you will need to reduce the volume of wastewater that you discharge. One option could be to improve or upgrade your current process machinery to more water efficient devices. Changes to or streamlining operational processes can also provide opportunities to reduce water use and, over a long period, what seems like a small initial saving all adds up. Another way could be to look at recycling the water you use. If you can reuse the water from one process for a second process that requires a lower purity of water or only needs a simple treatment, this could provide you with a cost-effective secondary supply. With its in-depth engineering and environmental expertise, Hydro International can help with specific solutions.”

Many companies use water as part of their processes, from cleaning vegetables to brewing beer, and being able to filter and, as appropriate, reuse water is critical. The Hydro Grit King® is a product specifically designed for grit and sand removal, which works for a wide range of specific gravities and flow rates. There are also products for primary settlement and filtration of wastewater, such as the Hydro MicroScreen™ which filters solids through a membrane. A free online calculator has been created to help you find out how much our Hydro MicroScreen™ treatment systems could save you on trade effluent costs (see www.hydro-int.com/trade-effluent).

As well as its range of products, Hydro International offers consultancy through its Hydro-Logic® Services team. For businesses unsure of which system will work best for them, the consultancy team offers advice.

To find out more about Hydro International visit hydro-int.com.