Drainage engineers from Lanes Group have used new pipe cleaning technology to solve persistent drain blockage problems at a nuclear power station. They used a new Picote mini cleaner and an electro-mechanical cutter to clear drains in one of the two reactor halls at Heysham power station in Lancashire (pictured, above).

Steve Hackett, an engineer at the nuclear power station operated by EDF Energy, said: “Having an effective system for cleaning these effluent pipes is a big benefit for us.

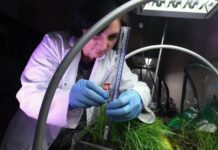

The stainless steel 75mm-diameter drains were installed when the power station was built in the 1970s. They are encased in concrete which has made them difficult to keep clean. They are also located within the radiologically controlled area (RCA) of the Heysham 1 reactor hall. This meant operatives had to wear specialist protective clothing and follow strict radiation protection procedures.

The drains, designated as ‘active’ because they could be contaminated with nuclear radiation, were cleaned in two stages.

First, a Spartan electro-mechanical cutter was used to break through blockage material. The device has a flexible cable with a rotating steel cutting head on the end for scouring the inside of pipes.

Then, the Picote mini cleaner was used to break up the blockage debris and push it into waste sumps, leaving the pipes clear. The device can be fitted with different rotating heads. In this case a flail was used.

Simon Nickalls of Lanes Preston said: “As the Picote cleaner is new, this solution has only just become available. We’re very glad it was so effective. We can certainly see how it could be applied to other hard-to-reach pipe systems.” More than 100 metres of pipework were cleaned, along with surface water gullies and sink outlets, in three key areas: the reactor basement area, the gas circulation maintenance facility, and the radiation effluent treatment plant.