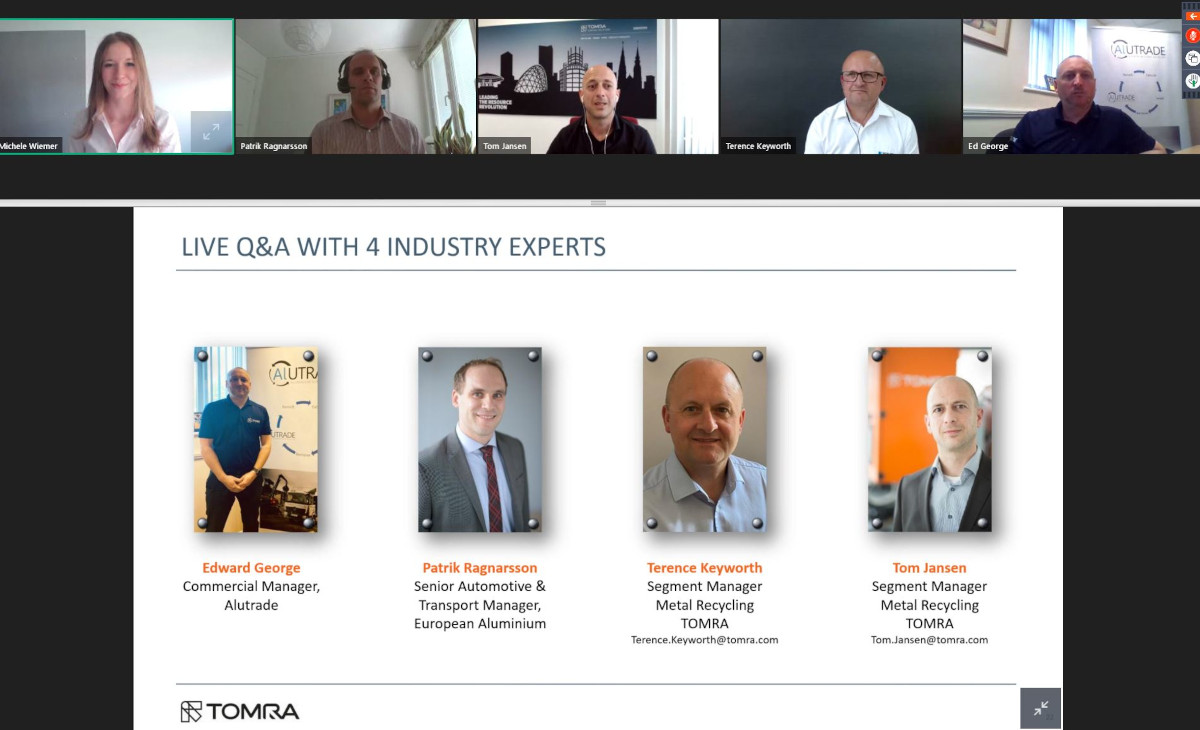

On 20 May 2021, metal sorting technology expert TOMRA Recycling held its first metals sorting webinar, which was entitled ‘Aluminium sorting industry outlook – key sorting technologies, innovations and opportunities in a circular economy.’ More than 200 participants from across the globe joined the 45-minute live session, said the firm.

An automotive expert at Alutrade, Patrik Ragnarsson kicked off the session, noting that the switch to electric vehicles has happened much faster than predicted, driven in part by the strict CO2 regulations set by the European Commission (EC). The targets are currently set at a 15% reduction for 2025 and 37.5% for 2030 – based on 2021 levels. However, he said trade association European Aluminium anticipates even more stringent targets will be introduced this summer to align with recently introduced climate targets.

Those car manufacturers who are unable to meet these targets will face hefty fines, so they need to use every available means to reduce CO2 emissions, which is why light-weighting is becoming increasingly important. Car manufacturers are also being incentivised to sell more zero- and low-emission vehicles, such as electric vehicles.

Demand for aluminium in Europe is anticipated to grow to around 18 million tonnes by 2050 – an increase of more than 40% compared to 2018, and this will include significant growth in demand in the automotive, construction and packaging sectors.

Some of the latest sorting technologies for aluminium scrap could play a crucial role in increasing recycling rates. Advances include improvements in x-ray transmission (XRT) technology for sorting and upgrading various types of aluminium scrap, including Zorba, Twitch and shredded aluminium profiles and sheets. Remelters benefit from having access to high-quality aluminium scrap sorted by X-ray transmission, and associated benefits of consistent quality, reduced energy consumption, reduced furnace cleaning and increased production capacity (or tap-to-tap time).

During the webinar TOMRA’s Segment Manager for Metal Recycling, Tom Jansen cited the example of an aluminium remelter who had installed XRT technology, and had thereby increased the amount of post-consumer scrap used for remelting from 25% to 50%, resulting in increased profits of €1.5 million annually. At the same time, the remelter’s energy consumption was reduced by 6% and its production capacity increased by 2%, he said, resulting in a €1 million increase in revenues.

TOMRA Recycling’s X-TRACT X6 FINES sorting machine includes a high-resolution sensor and it provides sharper x-ray images than the standard XRT version and offers higher precision on small and thin objects such as copper wire. Participants heard about TOMRA’s X-TRACT unit for magnesium removal which enables the removal of magnesium and the superlights fractions from aluminium to create cleaner aluminium fractions and process material with more stable output quality.

All sectors of the aluminium industry need to increase the amount of recycled aluminium being used in new products, and sensor-based technology will play a vital role in helping the industry increase recycling rates to achieve the low carbon roadmap set out in the European Aluminium Vision 2050 report.

Another contributor was Edward George, Commercial Manager at Alutrade, a specialist aluminium recycler in the UK. He said 70% of Alutrade’s business is aluminium extrusion and 30% is aluminium can-to-can recycling, with the material sorted, cleaned then sold to remelters around the world to be melted back into aluminium cans.

Alutrade has seen increasing demand for aluminium for both residential and commercial use in the building sector as businesses take advantage of the thermal, UV and aesthetic benefits that it offers when used in windows, doors and curtain walling. He explained how sensor-based sorting technology has changed the way the company processes material. Using X-ray technology from TOMRA Recycling, Alutrade can now process upwards of 100 tonnes per month of post-consumer waste from demolished buildings or replacement windows and doors, he said. The aluminium found in these items contains other metals such as copper, brass and zinc which previously had to be manually separated. Now, using x-ray technology, Alutrade is able to meet high demand from the global fenestration sector for high purity pre-consumer and post-consumer aluminium scrap, offering a full closed-loop recycling solution.

If you were unable to attend the webinar but would like to receive copies of the presentation, visit: https://solutions.tomra.com/en/en/metal-webinar-recordings.

TOMRA Recycling will be participating in the Greener Aluminium Online Summit which takes place from 2-3rd June 2021. Terence Keyworth will deliver a presentation at the event.