A flooding incident in North Macedonia in August 2020 threatened the country’s supply of electricity. Motor drive manufacturer WEG describes the subsequent drainage project.

The incident included the flooding of a coal mine beneath a thermal power plant managed by the state energy company ESM-North Macedonia.

More than 300,000 m3 of water flooded the lower parts of the mine, effectively disabling its operations. The plant is an integral part of the country’s energy system, generating 70 per cent of its power.

The drainage work was undertaken by a partner of ESM, Simtech Solution, a specialist in automation and SCADA systems, which also has an interest in power management in the water sector.

The situation of a natural disaster was a first for the firm, and the urgency was clear to Igor Novevski, projects & business development at Simtech.

“We only had a couple of days for project planning to devise the technical solution and three weeks to execute the entire project.”

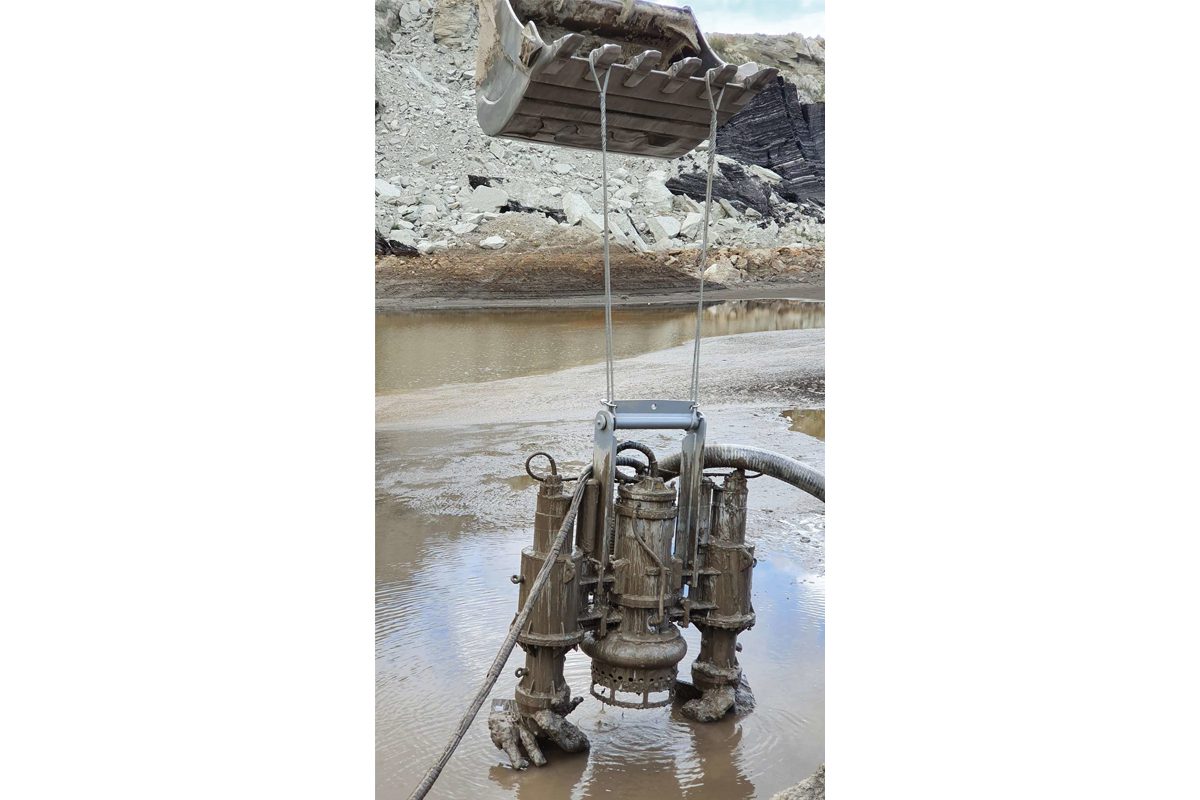

Practicalities included securing the supply of several heavy-duty pumps to remove all the sludge from the mine. Three 110 kilowatt (kW) pumps, made by Tsurumi of Japan, and three 90 kW pumps, by Dragflow of Italy, were delivered by TETRA DOOEL Bitola North Macedonia, the local distributor. All were supplied with electrical equipment, but something else was needed: an effective start-stop control system.

Soft-starters are essential to operate these pump motors safely and reliably — especially in a time-critical project.

Simtech Solution is an official distributor for WEG, a firm that was recruited to help, and which was known to have a large stock of parts in Germany, and to be equipped for a quick response.

Simtech Solution already had experience of WEG’s SSW06 Series Soft-Starter, designed to accelerate, decelerate and protect three phase induction motors. This time, it opted for the SSW900 soft-starter from WEG, a decision dictated by the performance of the latter.

The SSW900 features energy savings, embedded protection and extended durability of the electric motors. The equipment is fitted with a built-in bypass, which contributes to extending the starter lifetime, optimising the electrical installation and reducing heat dissipation.

Simtech Solution also opted for the SSW900 for its fault history and diagnosis capabilities, troubleshooting with date and time, and network communication interface.

The SSW900s’ compatibility with digital systems and human machine interfaces (HMIs) was also helpful in light of ESM’s requirement to integrate several PT100 thermal protection probes during the project.

Even with the right systems in place, there was another major challenge that the project would have to overcome: COVID-19.

Long-distance working

A challenge was to find a way to communicate the technological knowledge on how best to

implement and install the SSW900 soft-starters when travel and face-to-face meeting opportunities were so limited. Whereas WEG’s training would normally be held at its facilities in Germany, this time, it turned to online training organised by WEG International Trade, Austria.

“We’ve got colleagues in Brazil that are specialists in automation,” said Kamil Rygiel, sales account manager at WEG. “Every single training session was led by them, accompanied by regular remote communication throughout the project.”

This regular contact for different issues and topics throughout the project helped guarantee a smooth installation, helped further by Simtech Solution’s prior experiences with WEG’s SSW06 Series Soft-Starter.

Despite the challenges of a short time frame and the ongoing pandemic, the drainage project was completed in record time, and the technical solution was delivered to the end client. But what improvements should come next for ESM?

A plan is underway to integrate SCADA into the ESM plant’s enterprise resource planning system (ERP), and WEG is keen to publicise the availability of this automation capability before too long.