A utility in Dubai is a step closer to replacing its industrial pump bearings with grease-free water lubricated parts. The Canadian firm behind the technology, Thordon Bearings, explains more about the application.

The grease-free bearings are to be installed in desalination plants across the United Arab Emirates, which are run by Dubai Electricity & Water Authority (DEWA).

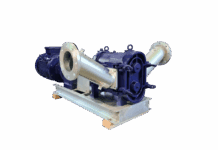

In the first six months of this year, Ocean Power International (OPI), Thordon Bearings’ Dubai-based distributor, supplied bearings for installation to 20 butterfly valves and 7 brine recirculation and vertical pumps, respectively.

OPI Managing Director, Rafid Qureshi said: “After hearing about the issues that DEWA was having with the original bearings, we proposed a solution that included ThorPlas-Blue [bearings]. After checking load calculations and ensuring operating pressures did not exceed the bearing material’s 45 MPa (6,527 psi) tolerance, we machined and fitted the Thordon bushings. Since that first installation, we have replaced pump and valve bearings at several power generation and desalination plants across Dubai.”

In 2019 for example, OPI and Thordon completed bearing retrofits at the OPI workshop for a de-mineralization pit pump after fabric lined metal bearings had worn out. And in May last year, 20 vertical pumps and 6 brine recirculation pump isolation valves at the OPI workshop were retrofitted with the Thordon polymer material.

“The bronze bushings originally installed in the vertical pumps were wearing out and causing frequent breakdowns every 6-8 months,” said Qureshi. “Unfortunately, there were multiple components that failed as a result of the bushing failure, forcing DEWA to find a longer lasting, more reliable solution.

“As the medium in these pumps is seawater, the new bearings had to be corrosion resistant, and capable of withstanding high operating speeds and temperatures up to 80°C (176°F). ThorPlas-Blue was deemed the ideal bearing grade for this kind of application.”

Since DEWA began operating their vertical pumps with the ThorPlas-Blue bearings, there has been zero downtime or increased vibration, Qureshi said.

By installing the bearings, “DEWA has saved about US$50,000 in downtime, eliminating unplanned maintenance and the costs associated with grease and spare parts procurement. Similar reductions in operational expenditures have been experienced across all of the company’s facilities following the Thordon installations,” he said.

The ThorPlas-Blue bearing can be used in all types of industrial pump applications and is an ideal replacement for bronze and other non-metallic bearings. It is available in a wide range of sizes and is easily machined to the dimensions required.

Developed as a maintenance-free alternative to greased bronze bearings, ThorPlas-Blue is a proprietary engineered thermoplastic bearing capable of dynamic operating pressures up to 45 MPa (6527 psi) and can easily be back fit into virtually all applications where greased bronze is currently installed. Higher pressures may be possible following a Thordon engineering review.

“The elimination of grease not only offers obvious cost benefits, but the bearing material is much safer and cleaner to operate than other conventional pump bearings,” added Brand.

The most recent projects involve the retrofitting of ThorPlas-Blue bearings to potable, seawater and fire-fighting pump non-return valves at Dubai desalination plants D, G, L and M.

OPI hopes to have converted more than 60% of all DEWA pump bearings to ThorPlas-Blue or SXL by the end of 2022.

“Thordon’s bearing material certainly fits well with DEWA’s commitment to adopting more sustainable, reliable and economically efficient technologies. It can help DEWA maintain a competitive edge while contributing to its Environmental, Social, and Governance (ESG) objectives,” said Qureshi.

DEWA currently has an installed capacity of 12,300 megawatts (MW) of electricity and 1.78 million Kiloliters (470 million gallons) of desalinated water per day, providing its services to over one million customers in Dubai.