As we enter the warmer months, waste and recycling sites are increasingly vulnerable to fire. Such risks are amplified by the presence of batteries in waste streams and in the vehicles and machinery used on waste sites. James Mountain offers pointers on fire safety.

The content of waste streams seems to change in an ongoing, unpredictable fashion. Batteries, however, are an increasingly common presence, found in items such as children’s toys and mobile phones. They’re also often used in vehicles and machinery on waste sites.

Regardless of size, shape, type or use, their high risk results from their propensity for thermal runaway. This occurs when the cells within the battery malfunction, due to physical damage, mechanical failure, overvoltage or overcharging. In this state, a battery will generate a lot of heat in a short space of time, leading to combustion, toxic gas emissions and potentially explosions.

A quick scan of the fires occuring on waste sites in recent times makes it fairly clear: Batteries are not being disposed of correctly and safely in domestic collection systems, much of the time. Instead, they are often simply thrown in with general household waste or recycling.

Waste streams in these facilities are often processed using heavy-duty machinery, making physical damage to batteries more likely. And these batteries are often surrounded by other combustible materials.

After a fire, operational downtime can be crippling to a waste and recycling business. Even if a fire is minor and causes little physical damage to equipment, a site can still be closed for ongoing risk assessments or investigations. A reactive approach – waiting for the inevitable to happen before doing anything to prevent it – can lead to prolonged operational disruption, as well as damage to facilities and reputations.

Case study one: Battery in the waste stream

In 2021, a UK recycling site experienced a large and damaging fire at its materials recovery facility (MRF). The fire started due to the presence of a battery in the waste stream.

The site had no fire protection in place, and the fire spread quickly. This led to whole-site loss, meaning the site needed to be rebuilt from the ground up. This entailed a several million euro investment to rebuild the entire facility, not counting the cost of operational downtime, reputational damage and any fines or sanctions enforced by the Environment Agency (EA).

The fire protection system installed after the fire amounted to a small fraction of this total investment.

Case study two: SRF production

In 2019, a well-known cement company wanted to start producing solid recovered fuel (SRF) using a shredding line at a nearby waste and recycling facility. The SRF was to be stored and used as a fuel source at the cement plant.

SRF is highly-combustible and the company conducted a full risk assessment, working with the waste and recycling facility. The firm opted to install two bespoke automatic fire protection systems:

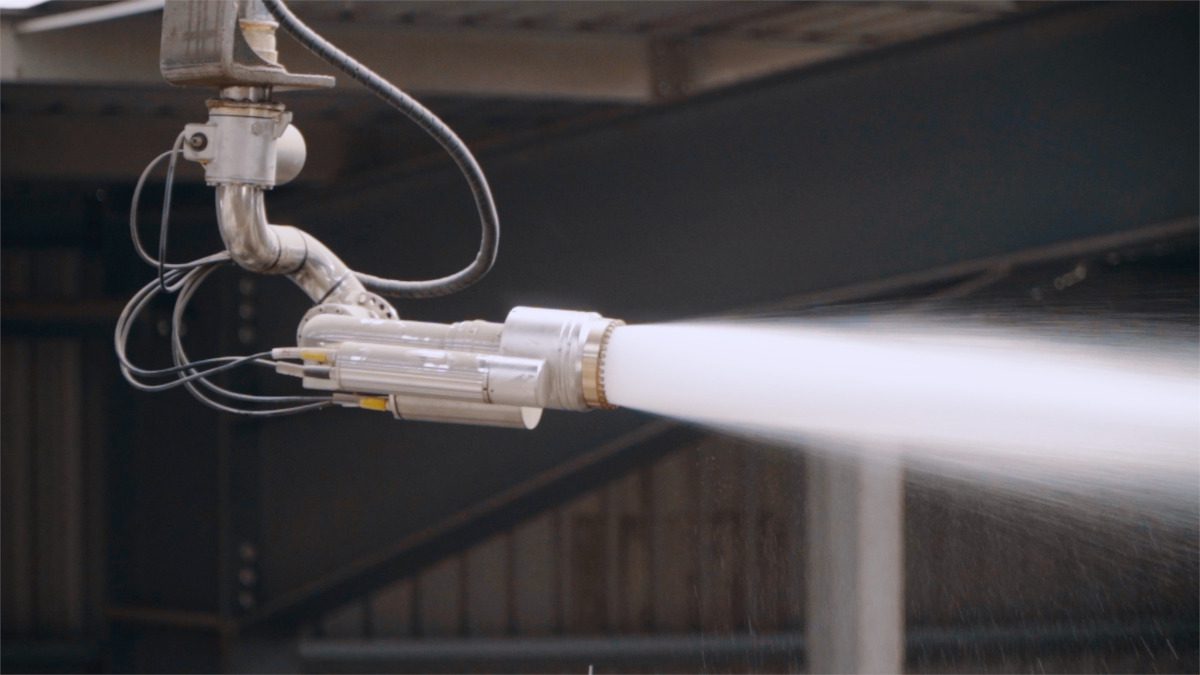

1. An automatic foam cannon and flame detection system and a local application deluge water spray system for the SRF production system.

2. A bespoke type-tested water spray system, activated by heat and flame detection for the SRF storage facility.

How can you take a proactive approach?

A few things to consider:

1. Site planning and mapping

A full site risk assessment should inform the site’s fire prevention plan. This will draw attention to any high-risk areas, such as those storing hazardous or flammable materials. The fire prevention plan should look to minimise these risks, for example, by storing ignition sources a minimum of six metres away from combustible waste.

2. Battery storage and processing

Inevitably, your waste site will need to store or process batteries at some point. When stored, batteries should be kept in weatherproof containers, away from any liquids. Any damaged batteries should be isolated, and lithium-ion batteries used to power vehicles or machinery should be removed from equipment and stored separately.

Before processing waste, your site should have checks and balances in place to identify and remove batteries. However, some will inevitably fall through the cracks. When this happens, you’ll need a suitable fire detection system that can detect hotspots quickly and implement the appropriate suppression technique to minimise the risk of thermal runaway.

3. Waste management and temperature checks

Waste should be regularly monitored to prevent a reaction between different types of material. When accepting waste, ensure you’re identifying the temperature of materials present. If any seem unusually hot, they should be quarantined to allow time to cool or to isolate the risk.

Regular temperature checks of waste piles will also minimise the risk of self-combustion. It’s also important to make sure waste isn’t kept in direct sunlight for long periods of time, or near reflective surfaces that can reflect direct sunlight onto the waste piles.

Once the waste is processed, for example through shredding or chipping, you should allow time for the generated heat during this process to be released.

4. Fire detection and suppression

The fire detection or suppression system that’s right for your site will depend on its individual risk assessment. These should be proportionate to the size of your site and should address the risks associated with the materials your site is processing, as well as the methods used to process these.