Alan Stewart of bearings distributor Rubix writes

Used in every conceivable manufacturing application, bearings keep production rolling by transferring motion and transmitting forces. Individual bearings use relatively little energy, but as they are in such widespread use and are also one of the most frequently replaced components, the sustainability of the bearings you use matters. By applying the 3 Rs of the waste hierarchy – Reduce, Reuse, Recycle – to this category of component, we can make a genuine difference.

Reduce

Is it possible to reduce the number of bearings used? Well, you can’t simply not use a bearing where one is required, but by extending their life you can reduce the total number of bearings used during that machine’s lifespan.

To ensure longevity, select the right bearing for the task at hand. There’s an incredibly wide range to choose from, many of which have been designed for specific applications and industries. In the food sector, for example, specialist commercial fryer bearing units have been designed that allow the hot cooking oil inside the fryer to enter the bearing and act as a lubricant. A completely different sector, yet one that also presents harsh operating conditions for bearings, is wind energy. Here, a raft of specialist bearings is available, including SKF Black Oxide Bearings which provide wind turbines with enhanced protection from corrosion, improved resistance against smearing, improved performance in low-lubrication conditions, limited risk of fretting and reduced risk of damage from aggressive oil additives. It’s important to do your homework or ask for advice on the bearing best suited to your specific needs.

Not only should the bearing be the right type, but it should also be of a good quality. Opting for a low cost, unrecognisable brand not only risks premature failure and costly downtime, but it may also lose performance over time which almost always results in wasted energy as most systems keep drawing power despite the drop or lack of output. Every second of wasted production equates to wasted energy and impacts on a days’ production targets.

Ensuring product is correctly fitted also has a part to play. Misalignment can lead to friction and vibration which can significantly increase energy consumption, plus the risk of premature failures. Whilst tools are readily available which allow for bearings to be easily and accurately aligned, designing machinery with bearings that don’t require realignment may prove to be a safer option. SKF Cooper Split Spherical Roller Bearings, for example, do not require the drive coupling or the cantilevered drive to be dismounted to replace the bearing; these bearing types are easily and safely replaced in situ, for maximum convenience.

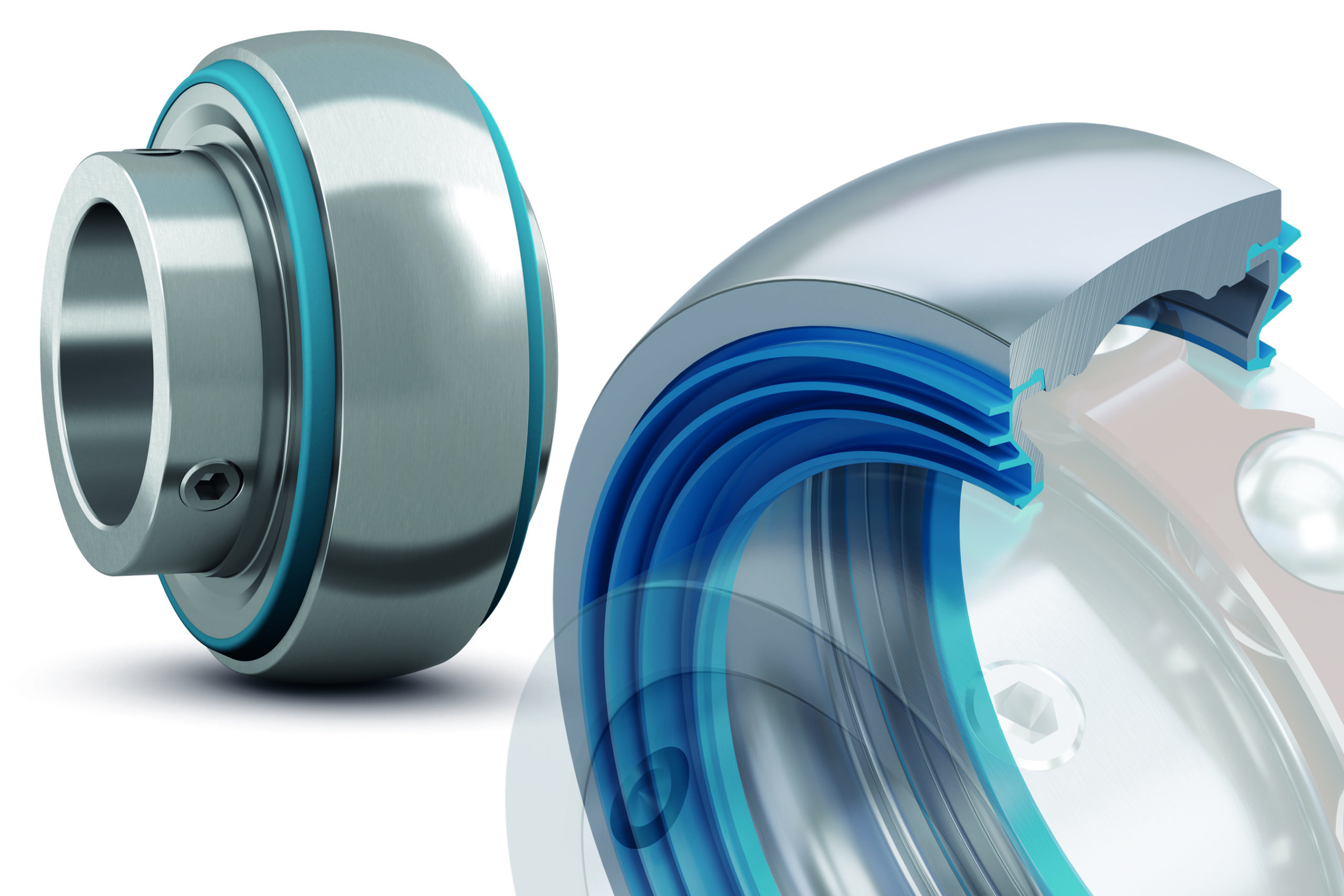

Reducing water and detergent usage in washdowns – a particular issue for pharmaceutical and food & drink sectors – is a major issue. What’s more, the waste water from this cleaning is often contaminated from excess bearing grease. This can be reduced by using sealed, re-lubrication free bearings such as SKF’s Food Line ball bearing units – Blue Range, which require 33% less heated water for cleaning when compared to open bearing units. Furthermore, there is no lubricant to contaminate the waste water, plus no cleaning rags and paper towels to dispose of.

Reduce the amount of lubrication you use by using sealed, re-lubrication free bearings. There are many to choose from but if you are looking at equipment that will be used in very demanding sites, such as mines and quarries, then you really need to look at something like SKF’s Three-barrier solution. It consists of a bearing housing – with labyrinth S seals, a lubricant to act as a contamination barrier and sealed spherical roller bearing. These three barriers protect the bearing from contaminants, leading to extended bearing service life on average three times longer than standard open bearings.

Sealed bearing units also help to reduce lubrication usage. Alternatively, automated lubrication systems can be installed to ensure the correct amount of lubrication is applied, reducing wastage and removing reliance on staff to undertake this task manually. Designed to lubricate individual machines or complete plants, automatic lubrication systems provide precise lubricant quantities at the correct intervals to all required points, minimising friction and wear, and optimising bearing and machinery service life. Not only is there a reduced environmental impact, but up to 50% savings in lubricant costs due to accurate timing and dosing of lubricants can be achieved.

Reuse

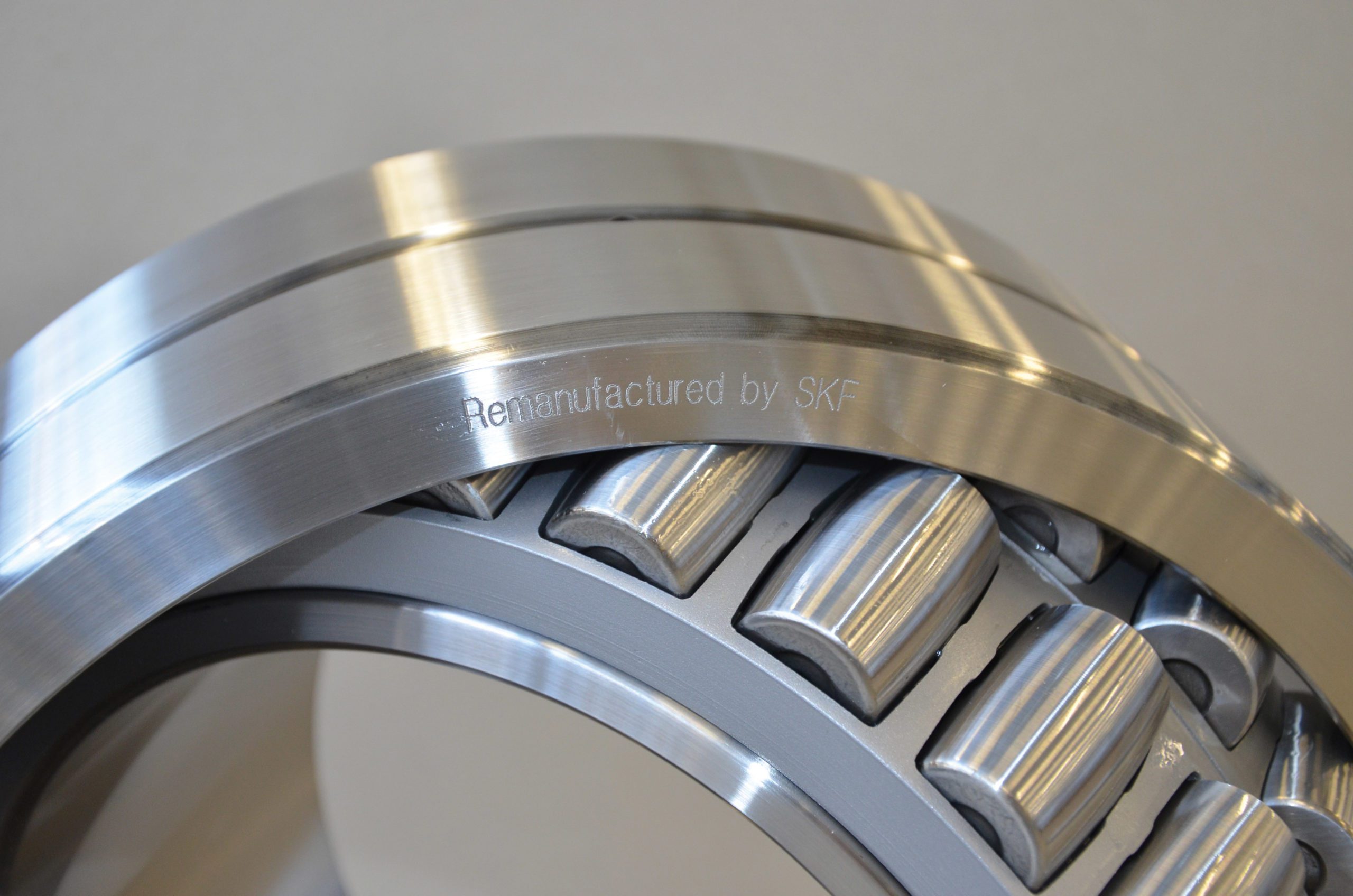

When it comes to Reuse, you may be surprised to hear that bearings can be remanufactured, which can significantly prolong bearing service life, as well as reduce cost and lead times. A large variety of bearing types can be remanufactured, including backing bearings, caster bearings, large sized bearings, slewing bearings and housings. Bearing remanufacturing can significantly reduce carbon emissions, consuming around 10% of the energy of making a new one. By extending bearing service, remanufacturing avoids the scrapping of components and wasteful use of natural resources.

In addition to bearings remanufacture, lubricants can also be reused in some cases. SKF’s RecondOil, for example, removes contaminants from used oils, and returns them to a cleaner, usable and high-grade state. Compared to a traditional, linear use, regenerating the oils allows for a significant decrease of CO2 emissions.

Recycle

Whilst the amount of steel per bearing is on the decline due to better bearing design and more efficient manufacturing methods, that steel still has a value as scrap. Not all bearings are easy to recycle though and normally only parts of them can be recycled. Check with the manufacturer.

Beyond the product

The 3Rs are a good starting point to help improve the sustainability of your bearings usage, but you can’t apply sustainability to the product in isolation. It’s important to take into account every aspect surrounding that product, including the manufacturer and its suppliers and distributors. Sustainability should encompass the use of raw materials; the manufacturer’s factory processes and utilisation of those materials; the amount and type of energy used to make the bearings; distribution and transportation. Does the manufacturer deploy the IS0 14001 Environmental Management System and the ISO 50001 Energy Management system across all of its sites, for example? What are their Net Zero plans?

Reducing wastage when it comes to bearings is not only good for the planet, but makes good business sense. A bearing that performs well over a long period of time is a bearing that won’t slow machinery down and won’t lead to expensive unplanned maintenance and downtime. Applying the 3 Rs to bearings is a good investment in the future, whichever way you look at it.

Alan Stewart is Rubix Bearing Product Manager with SKF Products. Rubix is a leading European authorised bearings distributor, selling over 100 million bearings annually. Read its new bearings sustainability brochure, produced with bearings manufacturer SKF, at uk.rubix.com/supplier/skf.