When fluid is pumped through a pipe in an intermittent way, the cost of transport is significantly reduced, according to a new study, a collaboration between the Okinawa Institute of Science and Technology (OIST) and the Polytechnic University of Milan.

In their proof-of-concept study, published in Scientific Reports, the researchers used numerical simulations to show that when they periodically switched a pump on and off, the fluid flow kept transitioning between a turbulent and laminar state. This reduced energy costs by up to 22% – a figure which the researchers say can be further optimized.

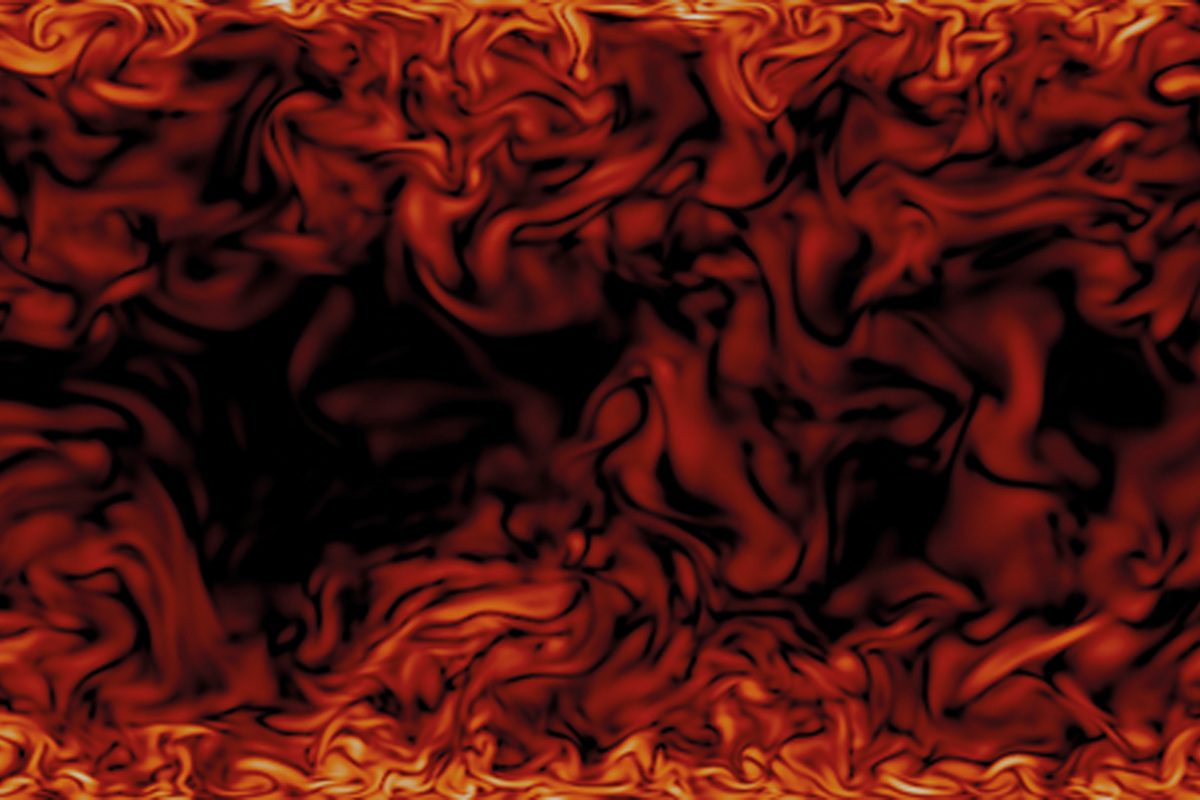

Laminar flows, like the kind you see when you slowly crack a tap open, are smooth, streamlined and energy efficient. Turbulent flows, on the other hand, such as those when a tap runs full blast, are chaotic and waste energy.

“If you inject ink into a laminar flow, you’ll see a clear line of ink moving down the pipe,

but with a turbulent flow, the ink diffuses as each fluid particle takes an unpredictable path. This chaotic motion at the small scales results in a lot of energy being lost,” explained Giulio Foggi Rota, first author and current PhD student in the Complex Fluids and Flows Unit. “Laminar flows are ideal for fluid transport, but when viscous fluids move fast and over large scales, the system naturally evolves towards a turbulent state.”

Savings in the pipeline

Reducing turbulence, and therefore the costs of moving fluids through pipes could bring numerous economic and environmental benefits. The transport of fluids makes up a significant part of the final cost of fuel, so liquid hydrogen could become cheaper for developed countries to transition to. For developing countries that are not yet able to make the switch to green energy, oil and natural gas could become a more affordable energy alternative to firewood, the use of which contributes to deforestation and produces more harmful pollutants than fossil