A seemingly unique solution for extracting carbon dioxide from building ventilation systems promises to assist with achieving net zero (and, so it’s claimed, carbon negative) building projects. Developed by Finnish firm Soletair Power, the process is reliant on accurate measurement of temperature, humidity and CO2, as instrumentation firm Vaisala explains.

The new system employs temperature vacuum swing adsorption (TVSA) to segregate CO2, before regenerating the adsorbent by ‘swinging’ to a vacuum. Soletair’s TVSA is able to capture CO2 with 99.9% purity, using less than 100ºC as the regeneration temperature.

Buildings and construction are responsible for 37% of the world’s CO2 emissions, so ambitious goals have been established to lower this figure during both construction and operation – the ultimate aim is to achieve carbon net zero buildings. There is also pressure from local and industry-specific regulations as well as broader, global requirements like the Paris Agreement, which requires a 50% reduction in CO2 emissions by 2030.

Soletair Power, founded in 2016, uncovered the potential for technology to reduce a building’s carbon emissions by capturing CO2 from its ventilation system and using it in the production of fuel or concrete, for example.

Why capture CO2 from buildings?

“Capturing CO2 from a building’s air, whether that be its inlet, exhaust, or circulated air, reduces its overall CO2 emissions,” says CEO Petri Laakso. “Our system also delivers cost-reduction, employee well-being, and sustainability benefits. For example, with CO2-lean air coming into the building you can reduce ventilation levels – which saves on heating, cooling, and energy, further reducing operational CO2 emissions. Lower CO2 levels inside offices and residential buildings also contribute to better health, well-being, and employee performance.

“To capture CO2, the air needs to be moving and ventilation systems do this work for us, and the air in buildings also tends to be around 20 °C, which is the optimum temperature for our process.”

In addition to capturing CO2 from the air passing through heating, ventilation, and air conditioning (HVAC) systems, Soletair Power has also developed an indoor CO2-filtering air purifier for meeting rooms and smaller office spaces, and an outdoor CO2 capture system. “Our outdoor device is very similar to the HVAC-integrated one, but with a housing around the unit,” says Petri. “We have one such unit in Duisburg, Germany, which is installed outdoors to capture as much CO2 as possible. The CO2 is then used by the company as a raw material for various industrial processes.”

Are carbon-negative buildings possible?

A major additional benefit of Soletair Power’s solution is that the captured CO2 can be used for other applications, including concrete production. “For concrete, the captured CO2 is used to create calcium carbonate, so you have the potential to achieve negative emissions when the CO2 is locked away from the atmosphere. This is one way we can help building owners to achieve net-zero emissions for the building’s lifetime by compensating for construction-related and operational emissions,” says Petri. “Carbon-negative buildings will also offer significant cost savings, meaning our systems can provide a return on investment within just a few years.”

Achieving net zero is no mean feat though, and the ability to do so can depend on various local factors, including how the power and heating for the building is generated. “To make a building into a carbon sink you need its electricity to be renewable and the heating from a source that minimises emissions,” Petri explains.

Soletair Power is currently working on several projects to create carbon net zero buildings. “These projects are using various advanced measures to reduce CO2 emissions during building construction and operation; in some cases, our solution is the final touch that tips the emissions over onto the negative side, and we should have some exciting results to share in the coming years,” Petri states.

Converting captured CO2 into sustainable fuel

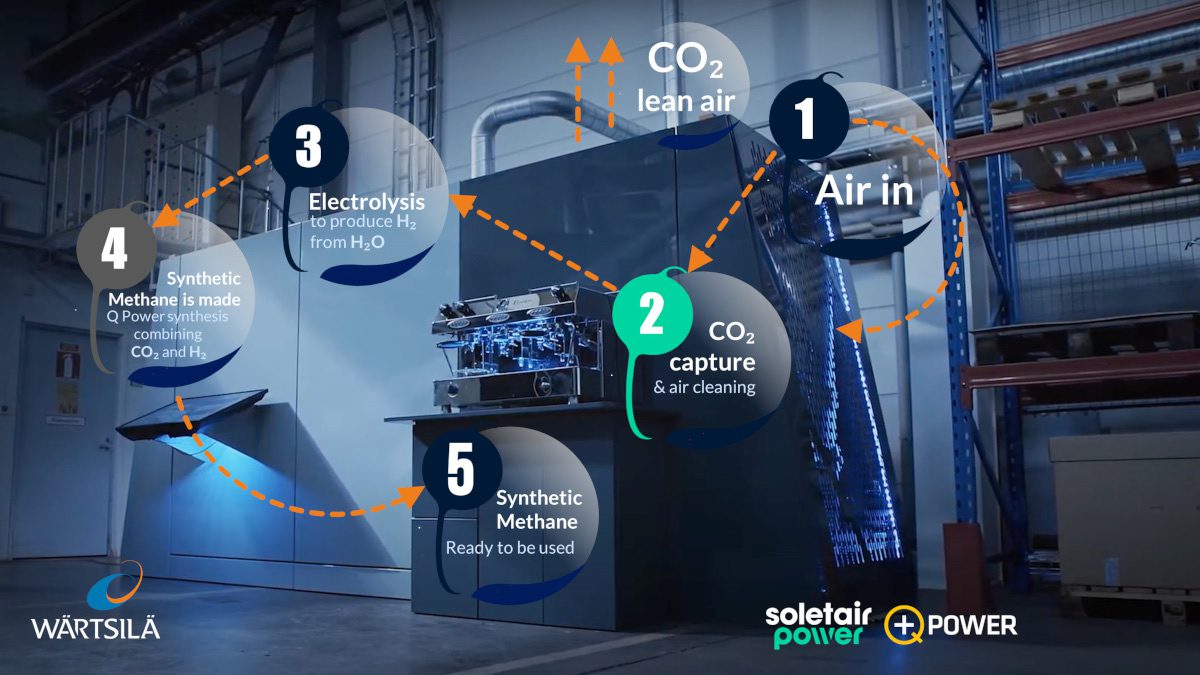

In autumn 2018, Wärtsilä, a technology firm with a focus on the marine and energy industries, approached Soletair Power about using extracted CO2 to produce fuels, before coming aboard the project with a seed investment in April 2019. The collaboration produced what is described as the world’s most compact device that uses air to create fuel. The Power-to-X demonstration unit, which was showcased at the Finland Pavilion at Expo 2020 in Dubai, used renewable power and CO2 from the surrounding air along with hydrogen from water to produce synthetic methane, which was then used to power a coffee machine for tradeshow guests. The companies have also collaborated on the development of an HVAC-integrated unit that captures CO2 from the inlet air at Wärtsilä’s Sustainable Technology Hub in Vaasa and supplies CO2-lean air to the building.

Accurate sensors are a key building block

The goal of the CO2 capture system is to reduce a building’s energy consumption while maintaining the same level of air quality inside. “Our system keeps the CO2 in the building at a low level, so that the ventilation can operate at very low levels in a demand-controlled mode. We need to be able to accurately measure the CO2 data to determine how much the system is capturing, which is where Vaisala’s sensors come into play. As well as CO2 sensors, our technology also uses sensors for humidity and temperature at various points in the process.”

Soletair Power uses the duct humidity and temperature transmitter HMD60, the CARBOCAP® carbon dioxide transmitter series GMD20, the CARBOCAP® carbon dioxide, temperature, and humidity transmitter series GMW90, and Vaisala’s handheld CO2 meter GM70 to take these readings.

Petri said they had learned from experience about the importance of specifying quality when selecting equipment. “We previously used cheaper sensors from elsewhere, but we found that the long-term stability of the equipment was lacking, which meant that we couldn’t guarantee accurate data as the equipment aged.”

Reliable equipment is also important when it comes to gleaning insights from measurement data: “The performance of our chemistry-based solution is affected by various factors including ambient conditions, so if you don’t have reliable data, it’s hard to judge why those changes have occurred.”

Soletair Power’s future plans include developing the TVSA technology to make the CO2 capture systems more compact and improve the sustainability of their operation. “We expect to continue our cooperation with Vaisala, and as our solution develops, we will likely need the support of their experts on which sensors to choose and how to calibrate them to work optimally in changing atmospheric conditions,” says Petri.