Photoionisation detection (PID) sensors are able to detect potential problems before they occur in the manufacture and use of lithium-ion (Li-ion) batteries, and the enormous variety of devices that use rechargeable batteries.

The safe utilisation of Li-ion batteries is a key concern for the developers of equipment such as electric vehicles, e-bikes, mobile phones and laptops. The risks posed by Li-ion batteries have been highlighted by a number of high-profile incidents. In 2006 and 2007, for example, millions of laptops and mobile phones were recalled due to safety fears relating to their Li-ion batteries, and in 2013, a Boeing 787 was grounded following electrical issues with the Li-ion battery in the aircraft’s auxiliary power unit.

Famously, in 2016, around 2.5 million mobile phones had to be recalled after complaints of overheating and exploding batteries. Extensive investigations revealed insufficient insulation material within the batteries and a design that did not provide sufficient space to safely accommodate the batteries’ electrodes, resulting in thermal runaway, which occurs when temperatures are raised by thermal or mechanical failure, short circuiting, or electrical abuse. In more recent news, there has been a 60% increase in e-bike fires in London in 2023 compared to 2022, and this number will continue to rise. As a result of the magnitude of this problem, and the global publicity which ensues, demand is growing for sensing technology that can detect faulty Li-ion batteries, during both production and operation.

The main safety hazards associated with failing Li-ion batteries are the ignition of the battery cell and/or the emissions of toxic gases. These gases include volatile organic compounds (VOCs), meaning sensitive VOC sensors can be used to check the condition of these batteries – either within portable detectors or in process/plant monitoring equipment.

The anode in rechargeable Li-ion batteries is typically graphite, the cathode is a metal ox-ide, and the electrolyte is usually a lithium salt in a (flammable) organic solvent. This elec-trolyte includes compounds such as ethyl methyl carbonate (EMC) which is known to be among the gases emitted by a faulty Li-ion battery. Conveniently, EMC can be detected by ION Science’s PID, so the developers of monitoring systems and equipment are able to design technologies that utilise ION’s MiniPID sensors.

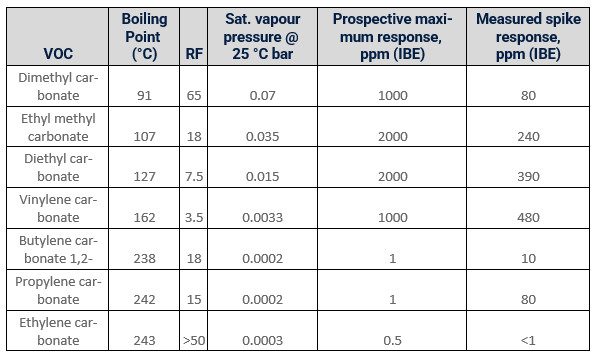

The Response Factors for VOCs commonly used in Li-ion battery electrolytes are pre-sented in Table 1: Evaluation of chemicals used in lithium-ion batteries.

Due to their specificity, PID sensors are the most commonly employed technology for the detection of VOCs, and ION’s MiniPID range includes the most sensitive PID sensor in the world, which makes it ideal for the detection of trace leaks from faulty Li-ion batteries.

Summarising, Peter Morris from ION Science says: “Prospective customers for our PID sensors in Li-ion battery applications include the developers of portable instruments, as well as the designers of monitoring systems for processes within battery manufacturing, as well as in the manufacture of EVs, e-bikes, laptops, tablets, phones and many others.”

(words: ION Science)

References:

Nedjalkov, A.et Al. Toxic Gas Emissions from Damaged Lithium Ion Batteries—Analysis and Safety Enhancement Solution. Batteries 2016, 2, 5. https://doi.org/10.3390/batteries2010005

https://news.samsung.com/global/infographic-galaxy-note7-what-we-discovered