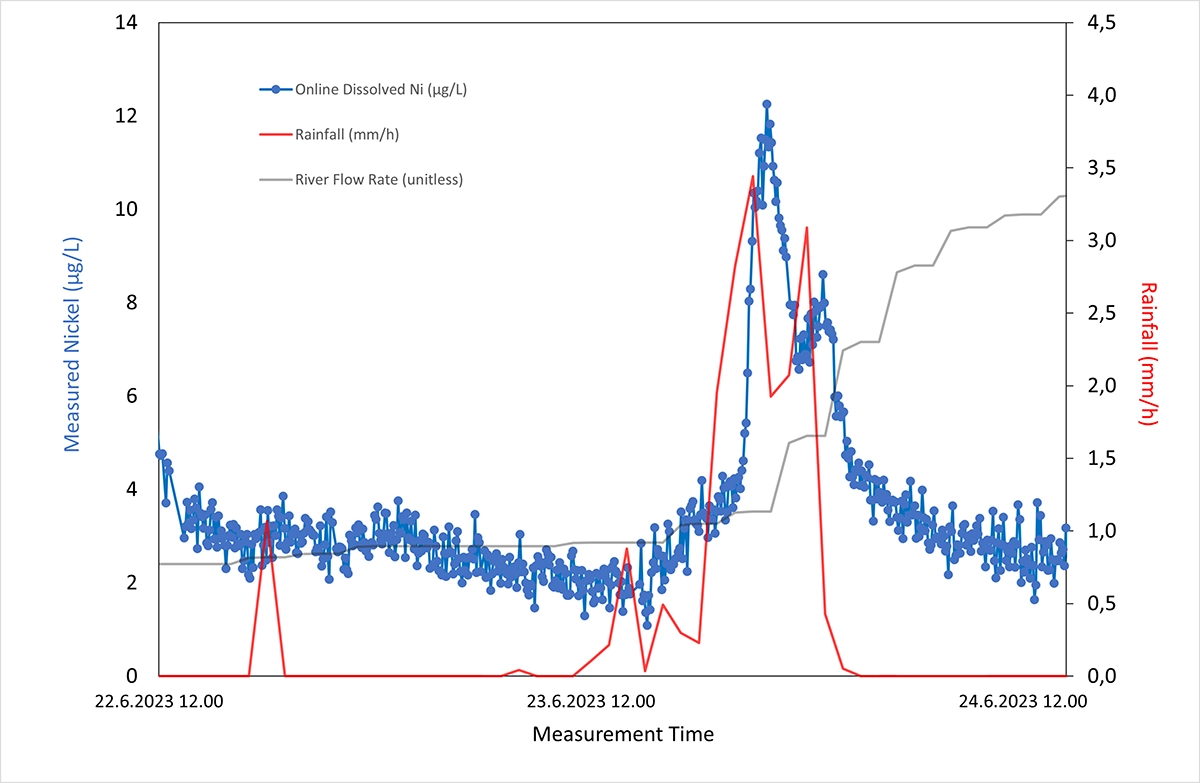

A new continuous metals monitoring technology was recently trialled at a river by a Talc production plant in central Finland. The trial was conducted to assess the possibility of avoiding the need to sample and analyse large numbers of environmental water samples. “The results were extremely enlightening,” explains Jari Sirviö, Development Engineer for Elementis, the plant’s owner. “Luckily, a heavy rainfall event occurred during the brief trial, and we discovered a rapid increase, and subsequent decrease, in nickel concentration that closely followed the rain. This strong correlation between rainfall and nickel provides an important insight into the behaviour of nickel, and raises a number of important questions; it also highlights the enormous benefits that can be gained from continuous monitoring.”

It is common practice globally, to monitor metals concentrations by sampling for laboratory analysis, and the plant had previously taken samples three times per week. In contrast, the continuous and automated monitor makes a measurement every 5 minutes, 24/7. “Lab analysis would not have been able to demonstrate the correlation between rainfall and nickel concentration,” Jari explains. “We are therefore delighted to see that this new monitoring technology can deliver greater insights into the factors affecting water quality, so that we can continuously improve our environmental performance.”

The new monitoring technology employs Micro-Discharge Optical Emission Spectroscopy (µDOES®), and was supplied by the Finnish company Sensmet.

Background

Employing over 1,300 people at more than 24 locations, Elementis is a specialty chemicals company with operations worldwide. The company is focused on distinctive, high-value solutions and products to improve performance and enhance sustainability for customers in the personal care and product performance specialties markets. The Elementis plant at Sotkamo produces Talc according to market demand, as well as Nickel concentrate as a by-product.

Talc is one of the softest minerals, and with platy and hydrophobic characteristics it adds value to a range of industrial products including paper, paints & coatings, polyester putties, plastics, ceramics, food, and fertilizers.

Nickel is used in a wide range of industrial applications such as the manufacture of stainless steel. However, its importance has been heightened in recent years as a component of rechargeable batteries – in electric vehicles for example.

Environmental monitoring

Elementis constantly aims to design better products that use less resources and create less pollution. In addition, the company has identified water management, waste minimisation and ecological impacts as material issues within its sustainability strategy.

A water treatment plant was built at the Sotkamo facility in 2021, using lime to raise the pH of site wastewaters and remove contaminants such as metals. In compliance with an environmental permit, together with Finnish environmental law, high quality process monitoring ensures the receiving environment is not polluted by the discharge, and includes an upper limit for nickel in the receiving river water of 0.034 mg/l.

During the period immediately after the installation of the neutralisation plant, a large number of laboratory samples were taken as the plant was optimised. This prompted Elementis staff to investigate the possibility of continuous analysis, which led to the trial of Sensmet’s µDOES® analyser.

Continuous multi-metal monitoring technology

Sensmet’s Micro-Discharge Optical Emission Spectroscopy, µDOES®, enables the multi-metal real-time analysis of aqueous samples. In addition to nickel monitoring, the technology can also be utilised to monitor elements such as lithium, sodium, cobalt, manganese, nickel, copper, and more.

The patented µDOES® technology is based on atomic emission spectroscopy. A micro-discharge (electric spark) is created directly inside the aqueous sample, causing a microscopic volume of the fluid surrounding the spark to be flash-heated to 10 000 °C. Molecules in the micro-discharge are dissociated into atoms, which are excited to their respective higher electronic states. Upon returning to their ground state, these atoms release their excess energy by emitting light at their characteristic wavelengths. The µDOES® measures this atomic emission spectrum to derive quantitative analysis of the sample, displaying measurements locally, and transferring data to the user’s DCS and database as needed.

Conclusions

The µDOES® analyser has provided the Sotkamo staff with new insights into the factors affecting nickel levels, which enables the development of mitigation measures. “Sensmet’s continuous monitoring technology has delivered a real lightbulb moment for us,” Jari Sirviö explains. “Now that we know about the correlation between rainfall and nickel concentration, we can investigate a range of options that could be employed to lower nickel levels, and with continuous monitoring we will be in a better position to evaluate the results.”

In recent years there has been a global trend toward greater use of continuous environmental monitoring. “This has been enabled by advances in technology,” explains Sensmet CEO Dr Toni Laurila. “However, as this trial has demonstrated, continuous monitoring delivers a range of other important advantages, that combine to further improve environmental protection.”