To reach Net Zero, manufacturing more products in the UK that contain recycled content, and ensuring that they are reprocessed domestically, will be crucial. One material that exemplifies progress in this direction is aluminium, says resource expert EMR, which outlines important initiatives and progress, below.

The aluminium recycling process requires only 5-10 percent of the energy needed to produce the primary metal, resulting in significant carbon emissions savings.

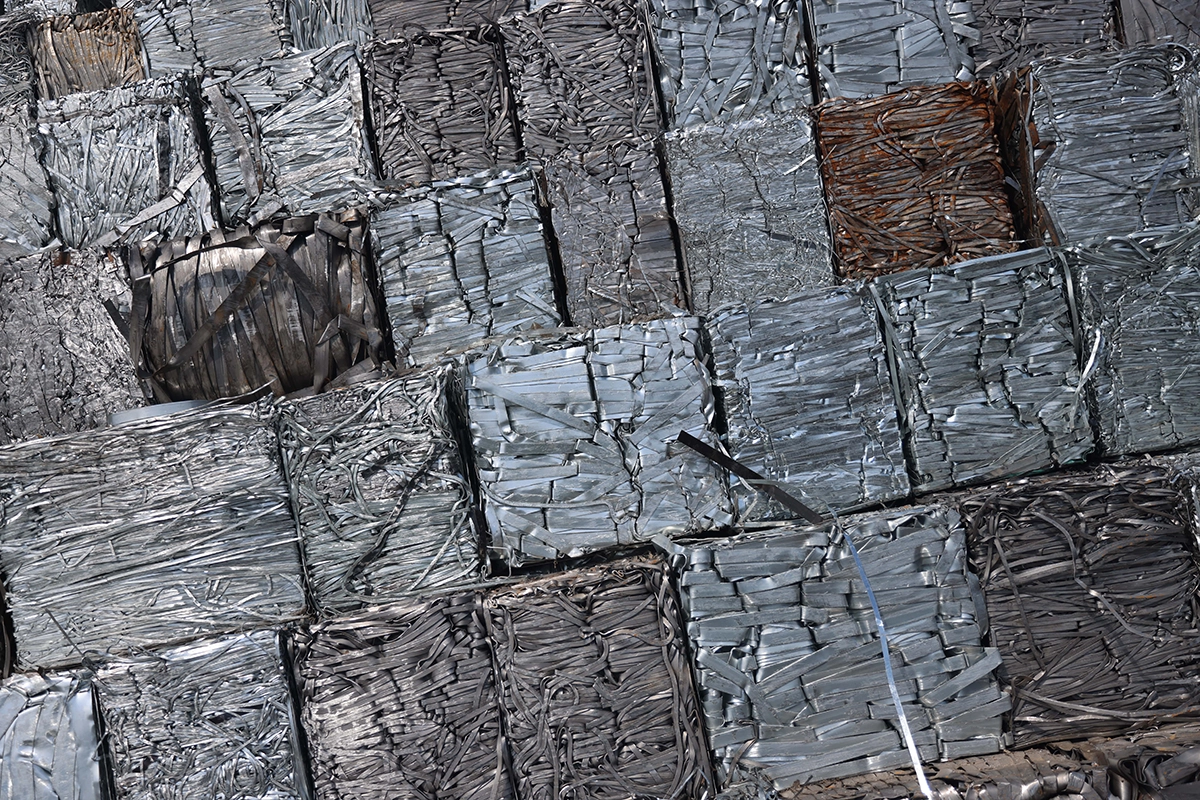

Currently, around two thirds (600,000 tonnes) of end of life scrap aluminium in the UK is exported for recycling, the highest rate in Europe.

To achieve the end goal of keeping 100% of our aluminium in the UK to be used in domestically manufactured products, preventing the need for the mining of new material and reducing unnecessary transportation, it will take a collaborative approach.

EMR has been working closely with a string of partners across the aluminium production supply chain to discover the barriers to using recycled content in the UK, and to figure out how to bring them down.

As the largest recycler of end-of-life vehicle (ELVs) in the UK, we have access to hundreds of thousands of tonnes of aluminium every year. So, as demand from manufacturers for recycled content increases, we are perfectly placed to work with the biggest producers to make these plans a reality.

We are also able to apply the lessons learned from other, similar partnerships we have collaborated in. For example, through the 2020 RECOVAS Partnership, with part funding from the Government’s Advanced Propulsion Centre (APC), we partnered with some of the largest vehicle manufacturers in the world, including Bentley, Jaguar Land Rover and BMW , to develop a circular EV battery recycling supply chain in the UK. And, as a result, we have a EV battery recycling facility launching in the UK later this year, along with our EV battery facility in Hamburg.

Last year, we also initiated the Re-Rewind Partnership, which saw EMR partner with experts to recycle rare earth magnetic materials. This project is part-funded by Innovate UK, and led to us establishing a wind turbine reprocessing facility in Glasgow.

Separation techniques

One of the main barriers to introducing more recycled aluminium into the manufacturing process is that current grade specifications for critical structural components are based on the qualities of virgin material.

Current recycled grades in the UK are a mix of alloys, so contain a mix of other metals, thus changing the make-up and so specifications of the material.

By working with our automotive industry partners, including leading Automotive Tier 1 supplier, Constellium, we aim to adjust the grade specifications for critical structural components and so use more recycled content, without compromising performance. Constellium are leading an exciting R&D project called CirConAl, with funding from the APC which is testing new scrap-tolerant alloy formulations for vehicle applications.

Additionally, EMR is constantly improving its recycling separation processes to reduce contaminants and recover higher grades of material, ensuring material can re-enter the circular economy, fit for purpose, and be used in domestically manufactured products.

The environmental benefits of using recycled aluminium are undeniable. By doing so, we can significantly reduce reliance on virgin materials, keep material within the UK and dramatically lower carbon emissions throughout the manufacturing process.

However, EMR is committed to demonstrating the strong business case as well. Our improved separation techniques enable us to recover more usable aluminium, resulting in higher yields.

Furthermore, substituting primary aluminium with recycled aluminium can lead to a dramatic reduction in the embodied carbon footprint of the manufacturing process.

By creating a higher quality product through advanced separation, EMR justifies the retention of end of life aluminium in the UK for further processing, instead of exporting it as lower-grade mixed alloys.

The growing demand for high quality, recycled aluminium materials in the automotive industry in particular, creates a compelling business case for collaboration.

We envision a future where recycled aluminium becomes the norm in UK manufacturing, and our commitment to working in collaboration to make this happen, not only benefits the environment, but also unlocks financial advantages.