A groundbreaking new reconstruction of 19th-century Britain’s water resources has revealed how limited access to waterpower during the Industrial Revolution helped drive the adoption of steam engines in Greater Manchester’s Cottonopolis.

Geographers and historians from the UK and Australia are behind the research, which reveals for the first time that local water shortages during the rapid expansion of the area’s textile factories likely played a role in their switch to steam power.

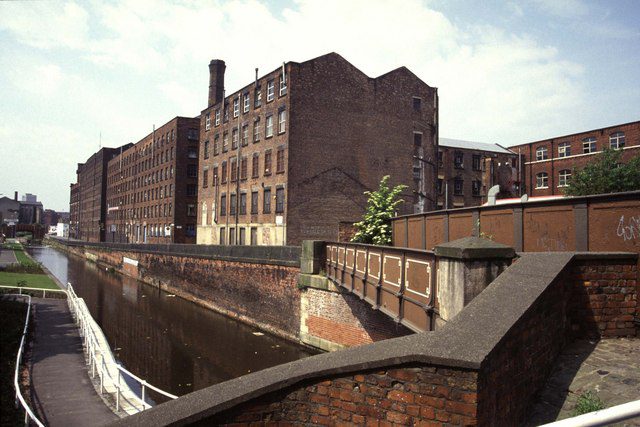

The research provides new information on the complex factors which drove Britain’s transition to steam power. Textile mills, traditionally powered by water wheels, were among the first industries to expand into new types of factories, which used machinery initially powered by water but soon adopted coal-powered steam engines to meet demand for their products.

Historians have long debated to what degree the Britain’s transition from water to steam power was influenced by British industry’s inability to access sufficient waterpower to support the needs of the country’s factories.

The team set out to investigate the issue by building an unprecedentedly-detailed geomorphological reconstruction of the water power resources available to 15,500 different mill sites in Britain.

Their high-resolution model was bolstered by historical climate data and the information contained in the 1838 Factory Return, the earliest comprehensive report on power use in textile mills.

They found that access to water power was in fact abundant across Britain as the Industrial Revolution gained pace, with one exception – Greater Manchester, one of the centres of the country’s booming cotton industry.

The researchers found that utilisation of most counties’ total water power across Britain was low, running from less than 2% to 14% in the most industrialised areas. Cottonopolis was the notable exception to that under-utilisation, with some of the most crowded Greater Manchester river tributaries reaching far beyond their power capacity.

The team suggest that as the Mersey Basin became increasingly crowded with factories as market demand increased, mill owners were forced to move towards steam power because the river could not provide sufficient waterpower to meet their needs.

The switch to steam was also likely compounded by the early 19th century’s unusually dry climate, which further reduced local access to water. As mills sought the most efficient way to maximise their limited access to water, owners adopted steam engines more rapidly, providing a template for industrialisation that factories across the country would soon adopt.

The team’s results are published in a new paper in the journal Proceedings of the National Academy of Sciences Nexus.

Dr Tara Jonell, of the University of Glasgow’s School of Geographical & Earth Sciences, is the paper’s lead and corresponding author. She said: “The First Industrial Revolution is one of the most intensely studied periods in British history, but our understanding of the factors that drove the widespread adoption of steam power is still incomplete.

“Our research draws together a vast amount of data to produce the first analysis of historical waterpower potential during a key period in British history, allowing us to scrutinise how much access mills of all sizes had to water during the Industrial Revolution.

“The fact that water was widely available around the country runs counter to some explanations of the shift to steam, such as an energy crisis caused by a water shortage. It also provides additional context for our understanding of how and why Cottonopolis embraced steam power quite early.

“We were fascinated to see for the first time that the cooler, drier climate conditions in Britain may have played a role in Cottonopolis’ shift from waterpower towards widespread use of steam power, in addition to the well-understood historical context of the cotton industry boom.”

The researchers found that manufacturers across other parts of the country, who had more ready access to water, often took a hybrid approach to generating their power. The team’s research further supports growing evidence that steam engines were first used as a supplementary power source to water wheels as waterpower use continued well into the latter half of the 19th century, longer than commonly believed.

The findings challenge the common view that the transition to steam power was sudden and sweeping. “The use of hybrid power systems was often an astute, best-business practice,” added Dr Jonell.

Dr Adam Lucas, of the University of Wollongong, is a co-author of the paper and co-investigator on the team’s ongoing research project. He said: “A common assumption is that British industry embraced steam power quickly, abandoning by the early 19th century the water power that had driven mills in Britain for nearly 2,000 years in favour of the perceived technological superiority of steam. Our research supports a growing consensus which has emerged over the last decade or two that the transition was in fact far more complex, and varied significantly from region to region.

“As our planet continues to heat up today as a result of fossil fuel use which accelerated during the Industrial Revolution, governments around the world are being urged to make new climate-driven decisions about power generation. We hope that research like ours can help provide new historical context for those important discussions.”

The team’s paper, titled ‘Limited waterpower contributed to rise of steam power in British ‘Cottonopolis’’, is published in Proceedings of the National Academy of Sciences Nexus.

The research, which is part of the ongoing ‘Away from the Water: the First Energy Transition, British Textiles 1770 – 1890’ project, was supported by funding from the Leverhulme Trust.