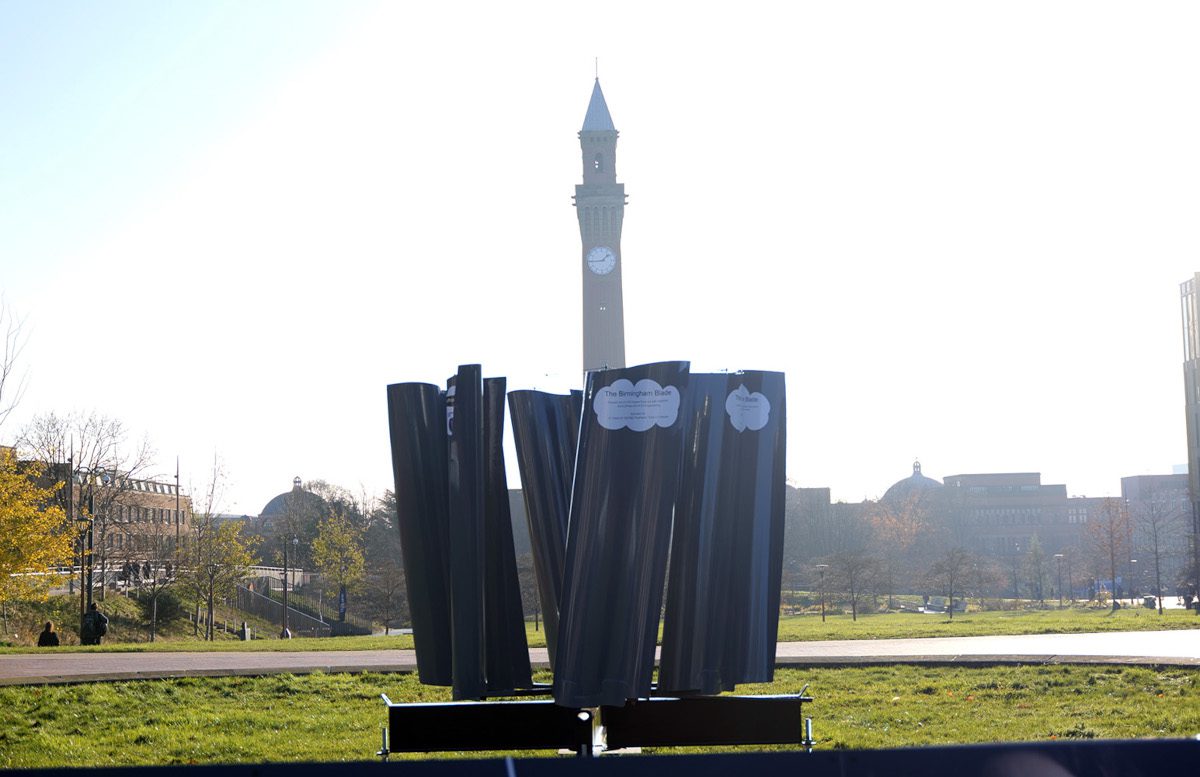

A group in Birmingham has unveiled what they describe as the world’s first urban wind turbine designed by AI, and tailored to the unique wind conditions of a specific geographic locale.

The collaboration between AI design specialists EvoPhase and metal fabricators Kwik Fab is said to provide a solution to one of the most pressing issues in the green energy landscape – how to produce small-scale, affordable, generators of clean wind energy.

EvoPhase used its AI-driven design process to generate and test designs intended to produce optimal efficiency at the kind of wind speeds found in Birmingham, which, at 3.6 metres per second are substantially lower than the 10 metres per second rating for most turbines.

“We needed a turbine that could capture Birmingham’s relatively low wind speeds while managing turbulence caused by surrounding buildings,” explained Leonard Nicusan, Chief Technology Officer of EvoPhase. “The design also had to be compact and lightweight to suit rooftop installations.”

EvoPhase found the optimal design for curved blades which spin around a central point, and confirmed that that it will be up to seven times more efficient than existing designs used in the Birmingham area.

Leonard explained why it was necessary to use AI to generate the design: “Using AI was essential for breaking free from the long-standing biases that have influenced turbine designs for the past century. AI allowed us to explore design possibilities beyond the scope of traditional human experimentation. We were able to generate, test, and refine over 2,000 wind turbine designs in just a few weeks, significantly accelerating our development process and achieving what would have taken years and millions of pounds through conventional methods.”

“Our evolutionary simulations have confirmed the Birmingham Blade is up to seven times more efficient than existing designs in Birmingham’s wind speeds and urban environment. The final design is not just a prototype — it is a predictive solution that is ready for real-world use.”

Developed by a research group led by Dr Kit Windows-Yule at the University of Birmingham, EvoPhase’s AI-led evolutionary design process mimics natural selection, this approach allows for simultaneous optimisation of many different parameters, avoiding traditional trade-offs between performance factors.

Kwik Fab produced the first iteration of the Birmingham Blade to demonstrate the feasibility of manufacturing the design. An aluminium version will be sited on a roof space in Birmingham for evaluation and testing, and the final product is expected to be available by late 2025.

The EvoPhase – Kwik Fab collaboration provides a rapid design and prototyping service, and the team is now working on another design for the very different conditions in Edinburgh.

Paul Jarvis from Kwik Fab is confident that there is sufficient talent and space in Birmingham to deliver quick turnaround from design to prototyping for wind turbines that are geographically tailored to specific local conditions around the rest of the world.

He said: “We can take a complex design, and manufacture and ship a prototype for testing within weeks. We’d like to work with organisations that want to make the most of wind power, a source of sustainable energy that is free, and present in every country.”

Since its launch in 2023, EvoPhase has expanded its AI-powered evolutionary design approach to industries beyond wind energy, including the optimisation of equipment for mixing, blending, and storing granular materials in the food, pharmaceutical, and chemical manufacturing sectors.

EvoPhase’s collaboration with Kwik Fab demonstrates the broad applicability of their predictive designs. It was made possible in part by the Manchester Prize which named the team as a finalist in the inaugural year of the prize in May 2024. The Manchester Prize is a multi-million-pound challenge prize from the UK’s Department for Science, Innovation and Technology to reward UK-led breakthroughs in artificial intelligence for public good.