In a study published in Nature, researchers have developed a method that they say is able to recycle all parts of a solar cell repeatedly without environmentally hazardous solvents. The recycled solar cell is said to have the same efficiency as the original one. The solar cell is made of perovskite and the main solvent is water.

Electricity use is expected to increase drastically in the coming years with the development of AI and the transition to electrified transport, among other things. To meet energy needs, without adding to emissions, will require a variety of different sustainable energy sources to work together.

Solar energy has long been considered to have great potential and solar panels based on silicon have been on the market for over 30 years. But first-generation silicon solar panels are at the end of their life cycle, which has created an unexpected problem.

“There is currently no efficient technology to deal with the waste of silicon panels. That’s why old solar panels end up in the landfill. Huge mountains of electronic waste that you can’t do anything with,” said Xun Xiao, postdoc at the Department of Physics, Chemistry and Biology (IFM) at Linköping University (LiU).

Feng Gao, professor of optoelectronics at the same department, added:

“We need to take recycling into consideration when developing emerging solar cell technologies. If we don’t know how to recycle them, maybe we shouldn’t put them on the market at all.”

One of the most promising technologies for next-generation solar cells involves perovskite. They are not only relatively inexpensive and easy to manufacture but also lightweight, flexible and transparent. Thanks to these properties, perovskite solar cells can be placed on many different surfaces, even on windows. Also, they can convert up to 25 per cent of the solar energy into electricity, which can be comparable to today’s silicon solar cells.

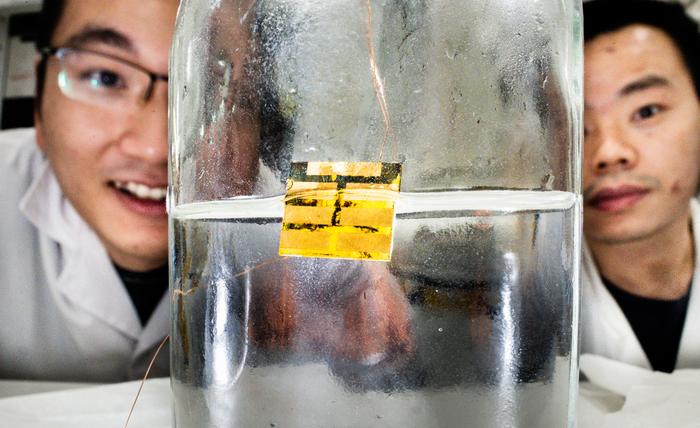

“There are many companies that want to get perovskite solar cells on the market right now, but we’d like to avoid another landfill. In this project, we’ve developed a method where all parts can be reused in a new perovskite solar cell without compromising performance in the new one,” says Niansheng Xu, postdoc at LiU.

However, given that perovskite solar cells currently have a shorter life span than silicon solar cells it is important that perovskite solar cell recycling is efficient and environmentally friendly. Perovskite solar cells also contain a small amount of lead that is necessary for high efficiency, but this also places great demands on a functioning recycling process.

In addition, there are also legal requirements in large parts of the world for producers to collect and recycle end-of-life solar cells in a sustainable way.

There are already methods for dismantling perovskite solar cells. This mostly involves using a substance called dimethylformamide, a common ingredient in paint solvents. It is toxic, environmentally hazardous and potentially carcinogenic. What the Linköping researchers have now done is to instead develop a technology where water can be used as a solvent in dismantling the degraded perovskites. And more importantly, high-quality perovskites can be recycled from the water solution.

“We can recycle everything – covering glasses, electrodes, perovskite layers and also the charge transport layer.” says Xun Xiao.

The next step for the researchers is to develop the method for larger scale use in an industrial process. In the long term, they believe that perovskite solar cells can play an important role in providing the energy when surrounding infrastructure and supply chains are in place.