Hydrogen heating technology firm HYTING has successfully completed a 2,500-hour durability test on its 10kW heat generator, the HG10, simulating 10 years of real-world operation with no component failures. Independent testing confirmed the HG10’s flameless, catalytic process produces heat without CO2, NOx, or particulate emissions, validating its potential as a clean alternative for industrial and commercial heating.

Tim Hannig, Founder and Managing Director HYTING, said the results “demonstrate the inherently long life and low maintenance requirements we’ve designed into our hydrogen heat generators.” He said the third-party tests also established the technology’s exceptional reliability and emissions-free capability.

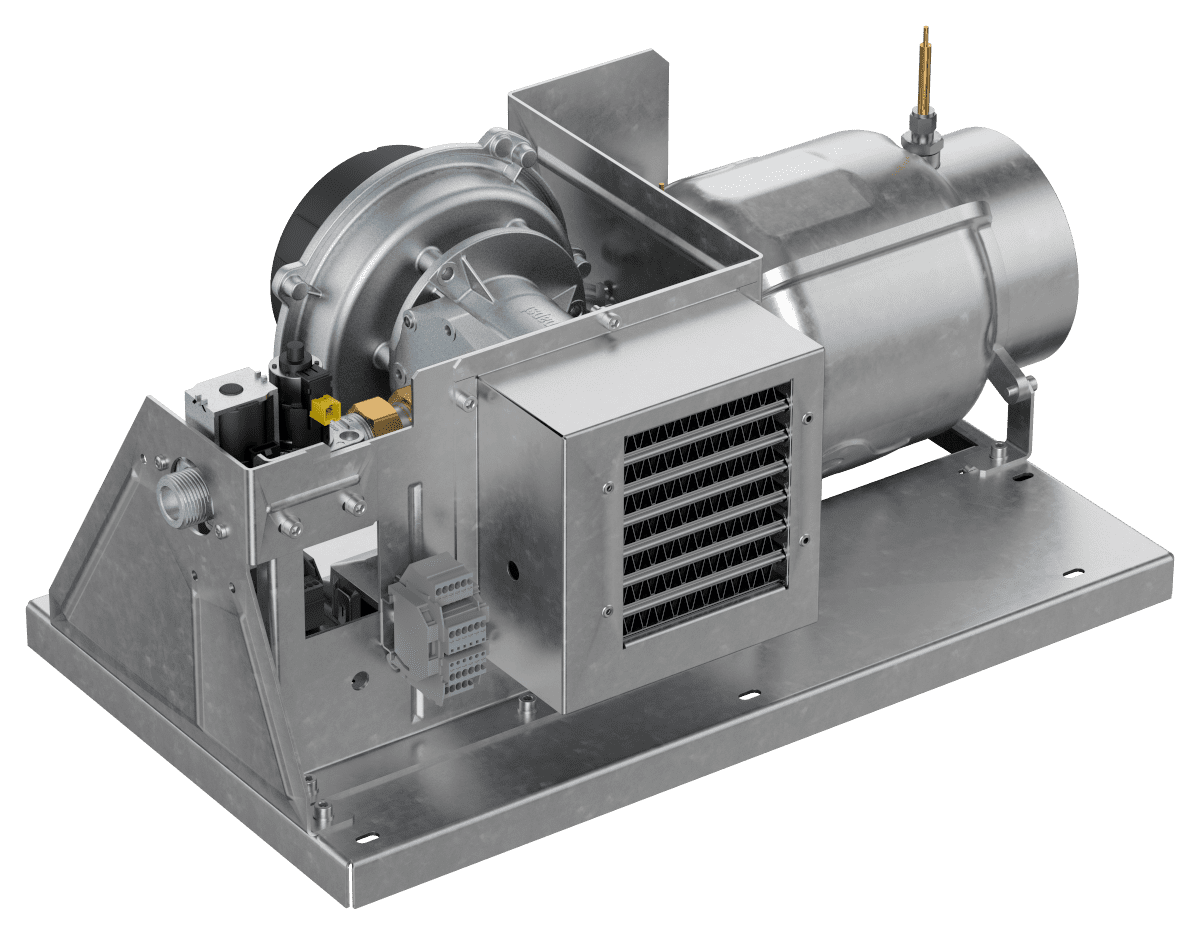

The HG10 is part of HYTING’s modular heating range, spanning 10–50kW, with a 150kW unit planned for 2026. Units are suitable for space heating in commercial and industrial buildings as well as industrial process heating up to 300°C.

This milestone follows a series of strategic developments, including the establishment of partnerships with ebm-papst and Kampmann for production and development; the first commercial customer (Flusys); and Gas Appliance Regulation (GAR) certification, enabling field testing across Europe.

The 2,500-hour durability test included continuous monitoring of exhaust gases, with no significant wear detected on any components, particularly safety-critical parts. This demonstrates both the durability and operational safety of this hydrogen technology, said HYTING.

On this evidence, the HG10 and HYTING’s modular range offer a scalable, zero-emissions alternative to conventional fossil-fuel-based heating systems.