A new review brings together the latest scientific advances aimed at understanding and mitigating ammonia inhibition in anaerobic digestion systems. Published in Agricultural Ecology and Environment, the study synthesizes more than a decade of research and highlights emerging tools that could help stabilize biogas production from nitrogen rich wastes such as animal manure, food waste, and sewage sludge.

“Ammonia inhibition is one of the most common and costly challenges in anaerobic digestion,” said corresponding author Junyi Ma of Beijing Forestry University. “Once ammonia reaches critical levels, methane producing microorganisms become stressed or inactive, which directly impacts energy recovery and system stability.”

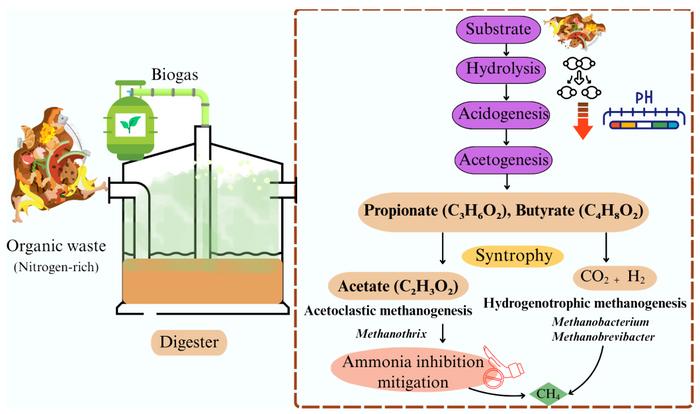

Ammonia exists in digesters in two forms, ammonium and free ammonia nitrogen. While ammonium can support microbial growth at low concentrations, free ammonia readily penetrates microbial cell membranes and disrupts internal energy and ion balance. Methanogens, the microorganisms responsible for methane generation, are particularly vulnerable.

The review explains how operating conditions such as temperature and pH strongly influence ammonia toxicity. Higher temperatures and alkaline conditions increase the proportion of free ammonia, making thermophilic digesters especially susceptible. Even moderate changes can shift a stable system toward inhibition if not carefully managed.

“Understanding how reactor conditions affect ammonia chemistry is critical,” said co corresponding author Junting Pan of the Chinese Academy of Agricultural Sciences. “It allows operators to anticipate risks before methane yields begin to drop.”

Beyond describing the problem, the authors provide a detailed assessment of mitigation strategies currently used or under development. Traditional approaches include adjusting feedstock composition, controlling organic loading rates, regulating pH and temperature, and diluting nitrogen rich substrates. While effective in some cases, these methods can be costly, energy intensive, or difficult to implement at scale.

The review highlights growing interest in biological and material based solutions. These include bioaugmentation with ammonia tolerant microbial consortia, acclimation strategies that allow microbes to gradually adapt to higher ammonia levels, and the addition of conductive materials such as biochar, activated carbon, and magnetite. These materials can enhance microbial cooperation and improve electron transfer, helping digesters recover methane production even under stress.

One of the most forward looking sections of the review focuses on the role of digital technologies. Advances in sensors, automation, artificial intelligence, and machine learning now allow real time monitoring of ammonia levels, volatile fatty acids, and methane output.

“Early warning is key,” Ma said. “Machine learning can analyze complex data patterns and signal instability before a reactor reaches a tipping point. This opens the door to smarter, faster interventions.”

The authors also discuss the potential of synthetic biology to engineer methanogens with improved ammonia tolerance, although they note that practical deployment will require further research and careful risk assessment.

By consolidating current knowledge and identifying research gaps, the review serves as a practical reference for scientists, engineers, and biogas operators alike. As the world seeks sustainable solutions for waste management and renewable energy, improving the resilience of anaerobic digestion systems will be increasingly important.

“Our goal was to provide a roadmap,” Pan said. “With the right combination of monitoring, management, and innovation, ammonia inhibition does not have to be a barrier to efficient biogas production.”