LTS Systems UK has partnered with Prokol Polyurea coatings, the only CE Certified Pure Polyurea manufacturers in Europe with a whole of life warranty, to supply an innovative super-tough protective surface coating solution for concrete and metal tanks. Running alongside the company’s existing tanking, steel fabrication and process pipework manufacture and supply business, the pure polyurea coatings can also be used on flat roofs and decked areas as well as walkways and industrial floors, with the same operational life provision.

Where can it be used?

Suitable for all small to large-scale weather protection and liquid sealing projects, industry leading Prokol Polyurea waterproof coatings represent one of the toughest corrosion and weather erosion solutions available for industrial and civil engineers, according to LTS Systems. The partnership provides LTS customers access to a seamless and durable coating to increase the operational life of roofs, floors and containment systems.

Polyurea coatings are sprayed onto surfaces by a Prokol approved professional, to create an inert environmentally friendly finish in a number of colours. The spray is applied hot in two layers on a surface, consisting of base primer and top membrane. The process is characterised by curing times that take a matter of seconds, even when applied onto rough surfaces. Therefore the coatings are ideally suited to applications for the water industry and similar utilities, from tank linings to protecting steelwork.

Filling concrete cracks

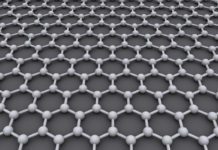

When applied to concrete, Polyurea can fill imperfections in the structure to give a smooth and durable finish. Coatings are also available for roofing and walkways, allowing the use of Polyurea solutions for other structures such as schools, hospitals, stadiums and railways. Perfectly tailored for the construction industry, Prokol products supplement new projects, design processes and regeneration schemes through a complete turnkey solution.

Prokol has global coverage, with decades of experience and understanding of every application. The coatings themselves are produced by elite chemists in the Prokol proprietary laboratory – ensuring full compliancy with EC guidelines NEN-EN 1504-2 and NEN-EN13813 – all while achieving a market leading CE certification across the range. In terms of durability, high UV resistance, temperature flexibility and waterproofing provide protection from the elements.

Further features include long-term flexibility, anti-slip properties and impressive thermal credentials – lowering heating costs and boosting safety in tandem. This gives Polyurea a distinct advantage over inferior mixed polyurethane and bitumen compounds.

Bespoke solutions can be specified, allowing customers to specify the suitable coverage of pure Polyurea for their individual construction. For every application, Prokol offers a 30 year manufacturer’s guarantee for operation without maintenance procedures, ensuring reliable cost-effectiveness for end users.

Non-reactive covering

Prokol systems are also totally recyclable into green composites and produce zero waste in most applications. Manufactured to contain no solvents or volatile organic compounds (VOC’s), Prokol systems have virtually no impact on the surrounding environment. These exceptional chemical credentials allow Polyurea coatings to be used for the inner lining of tanks and sensitive applications involving water, as no reaction can occur between the stored media and containment system.

The application process is also environmentally friendly, with no out-gassing occurring during the spraying procedure. Manufacturing itself is carried out at ambient temperatures and pressures, allowing the lowest possible energy input to be achieved. Ultimately, Polyurea coatings showcase non-hazardous credentials at every stage of production, application and service life.

Application expertise

LTS Systems claims to provide the expert advice needed to help clients choose the best possible combination, enabling the implementation of the optimum coating solution. Working with the requrements of the end user, LTS assesses the perfect protective match, taking into account application time, service life, maintenance and cost efficiency. As a result, Prokol coating solutions go hand-in-hand with LTS tanking and fabrication services – providing top quality construction with high performance protection. Decades of coating experience from Prokol and expertise from LTS achieves the ideal performance package for customers – permitting quality construction to be preserved for a long lasting operational lifetime.