Flygt flew to the rescue when a holiday home and caravan park in Cumbria decided to update its 18 sewerage pumping stations.

Flygt flew to the rescue when a holiday home and caravan park in Cumbria decided to update its 18 sewerage pumping stations.

CLOSE to Lake Windermere, the park has more than 700 caravans as well as static holiday homes and the managing company was keen to update all the sewerage pumping stations to an acceptable performance level with the aim of having zero breakdowns in the holiday season.

The existing pumping stations suffered from poor performance and the kiosk for the electrics and the control panels showed signs of age. There was also some concern that, without refurbishment, pipework could begin to leak.

A spokesman for the park explained: “The pump stations needed a serious overhaul to bring them up to date and with only limited annual funds dedicated to site refurbishment, it was decided that this year we would spend the money on pump station refurbishment in order to reduce downtime. The key issue was that any refurbishment would need to be completed in a very short period of time – in fact the one-month annual shutdown. We had a survey done on the performance of all the pumps and a number of recommendations were made for us to consider.”

The work was awarded to Flygt after it assessed the requirements. Field sales engineer Neil Siddons said: “We were asked to take a look at the condition of the sewerage systems and the effect it could potentially have on their visitors.”

One of the key recommendations was that the level controls should be repositioned or reset, in particular the stop/start and alarm switches on the pumps. “We wanted to move these to the recommended heights and replace any which didn’t meet the required standards,” said Siddons. “This would improve both the reliability and performance of the pumps.”

He continued: “One of the major risks identified was in regards to health and safety. Work on the pumps involved having to climb into manholes which could be in excess of 20ft deep and were slippery. We also felt it was important that the replacement pumps were removable to allow future work to be completed safely above ground. To overcome these problems and ensure a safer environment for our service engineers, we utilised our Flygt Easylift.”

Easylift is a lifting device designed in-house to comply with Work at Height Regulations when lifting pumps and other equipment from below ground level. The equipment reduces the risk when working over open spaces, manholes, sumps and wells and helps employees when lifting heavy or cumbersome materials from below the ground.

Siddons went on: “We positioned the pumps on longer length guide-rails to ensure that, in future, the pumps could be accessed easily and safely.”

Engineers completed the work during the recent shutdown, replacing large lengths of pipe work to ensure there would be no further leakage once the park re-opened to the public. Siddons commented: “We were on a very tight time scale with lots of work to do, but we were able to complete everything on time. It was critical that work on the sewerage systems was finalised before the holiday season began.”

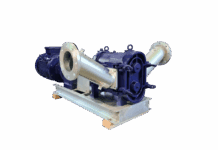

Further analysis of the pumping system found one of the main pumps to be in an extremely poor condition and in need of replacement. The new unit was fitted after the annual shutdown but was replaced without disruption to the operation of the park. The replacement was a new generation Flygt N-pump that features an anti-clogging impeller.

As part of the agreement, Flygt Service will maintain all eight pumps each year.