THE identification and tracing of leaks in smaller pipes could become a faster, more accurate and cost effective process thanks to a solution developed by the consultancy WRc with the support of the Technology Strategy Board.

Leak detection is something of a grail in the water industry where millions of pounds go down the drain every year as a result of leaks. As much as 40% of some countries’ water supply pours straight into the ground. In the UK, over 3bn litres are lost every day through leaks.

WRc was one of ten companies that were awarded funding in a Technology Strategy Board competition on water security.

The consultancy received £48k for a feasibility study of technologies that might speed up the process of finding and mapping leaks in pipes less than 100mm in width. The project was called INFO-Leak.

Leaks in the pipes that run under streets and carry water to houses are notoriously difficult to find. Finding them has involved monitoring changes in water flows at night when not much water is used with engineers then going to suspect areas to listen for water escaping. While the system works well enough for metal pipes, locating holes in plastic ones, which are increasingly being used in local mains, is more hit and miss. The process can often involve days of digging to locate a hole in a pipe.

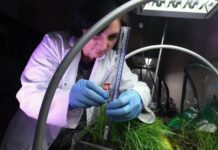

Julia Trew, Senior Project Manager for INFO-Leak, commented: “We wanted to investigate the possibility of replacing [ the conventional system ] with a lighter, thinner system using a camera and inertial navigation instead of having someone walking on top of the main.”

The initial feasibility study looked at a combination of three different technologies: fibre optic sound detection; inertial navigation; and live entry of tethered sensors to produce a new small diameter leak location system.

When it became apparent that inertial navigation and fibre optic cable weren’t close enough to market, the Technology Strategy Board allowed WRc to reallocate the unspent money to looking at alternatives.

WRc instead opted for a miniaturised version of the piezo-electric noise detection equipment used on its Sahara system (an international service for detecting leaks in large water mains). For location along the main, the final solution uses extra low-flow magnetics, a technique that makes use of a magnetic sensor coupled to some interface electronics inside the pipe.