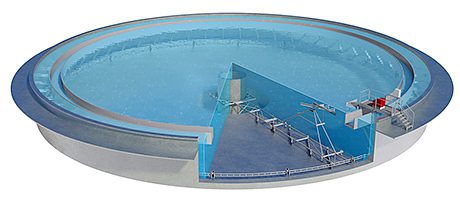

A new technology for circular sludge settlement tanks in wastewater treatment has the potential to achieve major operating and energy savings for all UK water companies, claims developer Hydro International. The Zickert™ Rotating Sludge Scraper builds on the success of proven technology for rectangular tanks.

With 90% of sludge settlement tanks estimated to be circular in the UK, the Zickert 3700 promises a widespread retrofitting opportunity as well as being ideal for new installations. It achieves the same lower-energy and high-sludge performance of rectangular Zickert scrapers and is suitable for primary, humus and final settlement tanks.

“The Zickert Rotating Sludge Scraper is a unique concept in scraper technology with great potential to upgrade the UK’s installed base of circular tanks, delivering significant advantages in through-life operating costs as well as odour control,” says Keith Hayward of Hydro Wastewater.

“Traditional rotating bridge scrapers need frequent service and maintenance. They can also be prone to wear and mechanical breakdown. Now a new way of removing sludge without a bridge or moving electrical connection point has been developed and proven.”