Moving to a circular business model can boost the bottom line. There is now much discussion and debate as to the best way to do it, finds Paul Marsh of Envirotec.

NO doubt about it, business is getting more enthusiastic about the circular economy. Addressing a seminar held by ecoConnect – “the UK’s green business network” – on the topic in Glasgow in early November, Iain Gulland, head of Zero Waste Scotland, one of the organisations charged with trying to make it happen, said things were now very different to five years ago. His own group has gone from “knocking on doors, trying to win hearts and minds” to now being approached by companies who are open to taking a fresh look at their business models, and identifying ways they could change.

“We’re seeing a big change in the appetite of business for this agenda,” said Jamie Pitcairn, director of Ricardo-AEA’s Scottish operation, at the same event. The concept has made the transition from feel-good add-on to bottom-line essential, something that might not have happened without the UK landfill tax.

James Forbes of law firm Burness Paull, which advises on planning applications in areas like renewables and waste, said Scotland now has a leadership role in this effort, helped by “very innovative” legislation. The Scottish food waste regulations, introduced in early 2014, have been a particular success in the effort to reduce waste to landfill, he felt.

Recycling: Old world thinking?

To many, the circular economy primarily means recycling. It was a very visible topic at the RWM show in September, in the seminars from local authorities, for example. Nigel Murphy, who was vice chair of Greater Manchester Waste Disposal Authority at the time of the event, mentioned that his council is still only capturing around 45% of waste for recycling, and they are looking at how to do more, in part through technologies like infrared separation of materials. He also cited a scheme in Manchester where they had collected food and garden waste from homes, which, once processed, had been put on sale as compost. It’s arguably a better bargain than what you get at B&Q and it helps educate people, he said. He also called for a national action to standardise recycling on the go, to make it mandatory.

A very different take on the recycling issue was apparent from Jamie Pitcairn of Ricardo-AEA at the Glasgow seminar in November. “If I could, I would ban recycling,” he said, explaining that, for one thing, recycling is still one of the worst recovery options, in terms of the waste hierarchy. We need to think bigger, he said, harking back to the early 1990s and the popularisation of ‘eco efficiency’ ideas: ‘let’s do more with less’, and that kind of thing. It was good at the time, he said, but now a fundamental shift is needed in our attitudes to waste and resources. And looking at local authorities and other organisations preoccupied with recycling targets, it was time to be clear about the fact that “we can do better”.

A focus of much discussion for the Glasgow panel was the idea of selling services rather than products. ‘Do I need light bulbs or light?’ or ‘do I need a computer or access to a central server?’ Consideration of these kinds of questions ╨ which prospective customers might now be asking – can yield business opportunities and competitive advantage in this new climate.

But people are still struggling to arrive at a good business model, particularly in the consumer space. A local bike shop proprietor asked the panel about his idea of leasing bikes as an alternative to selling them.

The only SME representative on the panel, Colin McLauchlin, head of lighting company Market LED, pointed out that the leasing and renting of products seems to have worked well so far in the B2B space with higher cost products, but it gets trickier to do with lower cost items. The first colour TVs were generally rented as few could afford one, but that changed as they got cheaper.

But even for a company like his, which might offer lighting on a rental or leasing basis, once the customer has finished with a physical product, he is still stuck with the problem of what to do with it, he said. “Where’s the second life?” Many products can be sold on, and a great way of getting the ball rolling in this respect is by working with procurement, an activity which Zero Waste Scotland’s Gulland said was “key to all this”, adding that his organisation has spent several years convincing procurement people that circularity is a credible way of proceeding.

And where a product is not fit for reuse, there are other ways of dealing with it than simply recycling, albeit methods that are still at a fledgling stage. On that score, the interest in things like product remanufacture appears to be gaining traction.

Rebooting old products

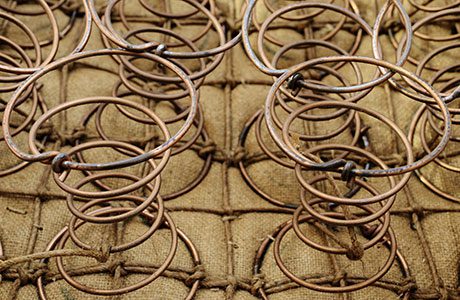

Remanufacturing involves restoring or repairing an end-of-life product to a level that meets or exceeds the original performance specifications. It is believed to be a £2.4 billion market in the UK.

The Scottish Government has committed £1.3 million to the creation of a research hub for remanufacturing, the Scottish Institue of Remanufacture, an announcement made in late October. Gulland commented that there are already around 60 companies in Scotland involved in remanufacture, “so we already have a base”, and the existing industry has also pledged a further £800k to fund the venture.

One of the challenges with concepts like remanufacture is getting used products back to the factory, or to a remanufacturing site, in a cost effective way.

To this end a materials brokerage service is to go live in Scotland in 2016, to aggregate recycled materials from collection points around Scotland. The new repository, The Scottish Materials Brokerage Service, is to help grow Scotland’s reprocessing sector and will also allow the public sector to generate more revenue from the materials it collects. It will also hopefully provide a greater level of certainty for would-be investors in this sector, helping secure certainty of supply for various waste streams.

Consumer electronics manufacturers also appear to be beginning to support the collection of end-of-life products. Dell Computer, now runs such a programme in the US, called Dell Reconnect.

At this point the circular economy appears to be coming into being via a bewildering array of different options and business models. Businesses may find it hard to know what is best for them, and this is where organisations like WRAP and Zero Waste Scotland appear to be able to help.

One project that is weighing up the different business models – whether it be leasing, incentivised return, or pure, simple product-life extention – is REBus, led by WRAP, with contributions from the Knowledge Transfer Network and academic groups in the UK and the Netherlands. It is focusing on the four key markets of electrical and electronic products, clothing, furntiure and construction projects, with some results expected in March.

Ben Peace of the KTN, speaking at RWM, said one of the next big challenges is coming up with practical ways of retaining the value in items that currently tend to go to incineration, things like dirty mattresses, old sofas, and smelly carpets.

Zero Waste Scotland advises companies, particularly SMEs, on embracing circularity, something that is still taking shape. He said he believed it was a transformation that would be led by the “designers, disruptive innovators, and entrepreneurs”, rather than by the waste sector itself. “But they won’t do it on their own,” he said, referring to the large scale cooperation which this new paradigm implies.