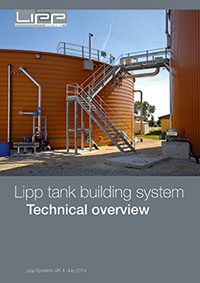

LIPP Systems UK has released a technical overview document for its proprietary tanks, designed to improve corrosion resistance and reduce total life costs in storage and anaerobic digestion (AD) applications.

The document outlines the advantages of the double-fold Spiral Seam tank (SST) construction system as well as detailing the materials involved, which are claimed to provide market leading levels of product quality and high yield in AD installations.

The document outlines the advantages of the double-fold Spiral Seam tank (SST) construction system as well as detailing the materials involved, which are claimed to provide market leading levels of product quality and high yield in AD installations.

The Lipp tank storage system is designed to be flexible with any size available from 3m up to 40m in diameter. The internal surface material is specified based on the substance to be stored in order to ensure wear and corrosion resistance, ensuring maximum service life. The tanks are self-supporting, an attribute of the “award winning Lipp Dual-Seam System”, a design said to have 40 years of reliable service across the world, including an estimated 3,000 tanks used in AD plants and over 50,000 worldwide. They can be designed as basic open-topped containers, gas storage tanks, bulk material silos, anaerobic digesters or as replacements for existing installations. The flexibility of design and construction allows each tank to be tailor made for the customer while remaining a cost effective solution that will provide superior levels of performance.