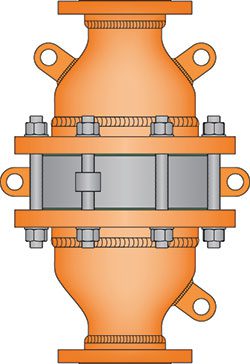

PREVENTING the propagation of pipeline explosions requires the use of flame arresters. Important improvements in this technology are claimed for a new range of arresters from Elmac Technologies.

The next logical step was to take the lessons learned from the development of the end-of-line arresters and transfer the technology to in-line deflagration flame arresters. This has apparently been achieved with Elmac’s new LCA and LEA series of flame arresters.

These new products are suitable for use with gases in explosion groups IIA1 and IIA and have model variants which include operating pressures up to 1.5bara, operating temperatures up to 160°C; short-time endurance burn capability of 10 minutes; high flow, low pressure drop characteristics; and a size range of 15mm to 300mm nominal bore.

In-line deflagration flame arresters are designed to prevent the propagation of pipeline explosions in their initial stages when flame velocities and associated pressures are at their lowest. As such these units are used in venting applications and where the proximity of the flame arrester to an ignition source is relatively close.

One common application of in-line deflagration arresters is flares. The flame arresters are installed in the gas feed lines to the flare to protect the rest of the plant from potential flashback. The use of a flame arrester in this application is essential as there is always a significant risk of flash back when operating within the explosive limits of a fuel gas.

The new LCA and LEA flame arrester ranges minimise the impact of using a flame arrester on the process, meaning higher flow rates are achievable with smaller flame arresters. Not to mention the fact that E-Flow™ in-line arresters are smaller, lighter and easier to maintain with significantly reduced fouling in the element.

Peter Evans, Operations Director at Elmac Technologies, said: “With the resources we have committed to implementing new methods of product design, and with the dedication and expertise of our technical team, to have produced six new arrester series in such a short space of time is most rewarding.”

Elmac can assist clients by specifying appropriate products for proposed new installations and plant retrofits.

In addition, Elmac is able to provide advice on the positioning of these products in an installation and to evaluate the suitability of flame arresters already fitted.