One of the UK’s first RHI-funded biogas plants is optimising its energy efficiency by installing a pipe network that benefits from low thermal conductivity.

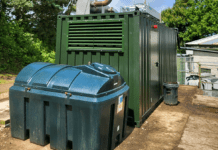

Strathendrick Biogas selected Flexenergy’s Flexalen pipe technology when developing a new Anaerobic Digestion Plant at Claylands Farm, Glasgow to fuel a combined heat and power unit. The plant generates renewable energy and natural fertilisers from agricultural by-products and distillery co-products.

In the project, the biogas produced by anaerobic digestion drives the CHP system, which in turn creates power that can be exported to the national grid, thereby creating revenue for the farm via feed-in tariffs. The plant not only delivers power, it also separates solids from liquid, enabling the liquid to be spread on the farm as fertiliser and the solids to be dried and used on the dairy farm as animal bedding.

The engine in the plant produces as much heat as it does power, with heat converted into hot water and carried to the drying unit via the low carbon Flexalen pipe network.

“Cost, quality, efficiency and ease of installation were all important factors when choosing the pipework for this project,” said Robert Kennedy, Director of Strathendrick Biogas Limited. “The Flexalen pre-insulated pipe system installed was the ideal technology for this situation being lightweight and highly flexible. The water tight bond between the corrugated outer pipe and the polyolefine insulation also satisfies the requirements for sustainable construction”.

The plastic pipe system also reduces heat loss potential over conventional pipe, resulting in improved overall energy efficiency, lower long term life cycle costs and extended operational periods between pipe replacements.

The new plant at Claylands Farm generates 4,200MWh of renewable electricity and 3,200MWh of renewable heat per year, along with the added benefit of low cost animal bedding and good quality fertiliser.

Kennedy added: “The biogas plant continues to perform above expectations and the ability to produce dried quality animal bedding further demonstrates the benefit of these systems to dairy farmers.”