A submerged membrane treatment plant installed by wastewater treatment experts Jacopa is still providing outstanding treated water quality for the Glanbia dairy in Kilkenny, 15 years after it went into operation, according to the firm. A further upgrade was also completed in 2006 to accommodate an increase in production.

In 2013 Glanbia needed an improved level of biological treatment capacity to enable its Ballyragget factory to expand, and called on Jacopa’s expertise in membrane bioreactor (MBR) technology to help achieve its aims.

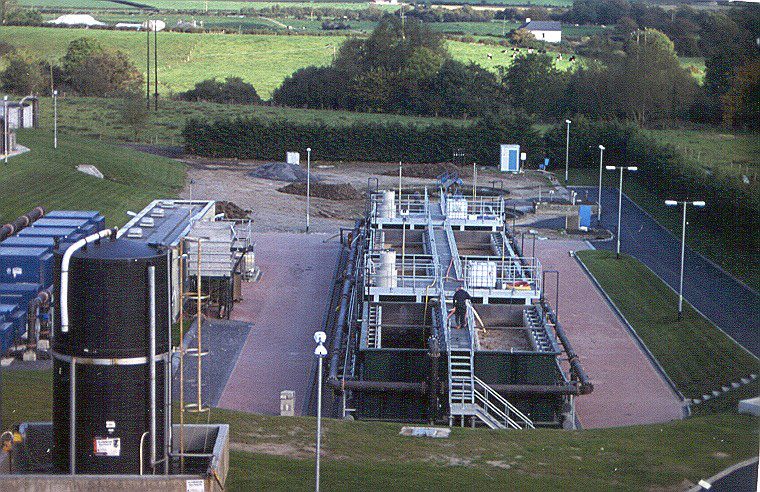

The upgraded plant is said to provide highly effective treatment of dairy waste, with up to 11,400m3/d of “outstanding quality” effluent for discharge to a sensitive salmonoid river.

What does the MBR do?

The MBR takes effluent from an existing oxidation ditch, and replaces conventional settlement tanks. The physical barrier provided by the membranes enables the quantity of MLSS (mixed liquor suspended solids) and loading on the oxidation ditch to be increased.

The plant design incorporates 140 membrane treatment units each containing 200 panels in a modular arrangement of 14 steel aeration tanks, which operate in two groups of four and two groups of three. Plant control is achieved by varying the aeration tank levels in proportion to the incoming flow.

Jacopa provided various additional services to Glanbia during the project – help with the design, inspections during installation, startup, commissioning and membrane cleaning.

Flat sheet membrane offering for the UK

The company is now offering an own-brand robust, cost-effective and low maintenance flat sheet membrane panel for the UK market. The panel has already undergone trials at live treatment works that show it can match the performance of established installations.

Jacopa Operations Manager Biological Products, Keith Wylie says: “The fact that the Glanbia plant is still providing an outstanding quality of effluent more than 15 years after it went into operation really shows just how durable and effective these systems are. Glanbia had enough confidence in the design and robustness of the original plant to commission Jacopa to design and deliver the upgrades in 2006 and 2013.

“We believe our own membrane panel, which is fabricated in sizes to suit the vast majority of existing UK installations, will provide an excellent cost-effective solution that the dairy industry and others can adopt as a reliable way to meet strict consents and enable expansion.”