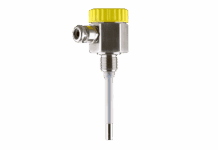

Wastewater treatment systems and services expert Jacopa has completely re-assessed and re-engineered its highly-regarded Copa circular tank rotary scraper range to produce an asset that – according to the firm – retains a high quality of construction and reliability at a competitive price.

The critical assessment has resulted in a focus on standardisation in metre increments, from 5m to 45m (a popular standard tank diameter). The company says it has tailored the new approach to ensure that it makes economic and practical sense for clients.

“It has been a tough challenge,” said Jacopa’s Operations Manager, Mike Dale. “But we were determined to succeed as the improvements have such significant benefits for clients. Standardisation has enabled Jacopa to reduce its proposal time to less than 2 to 3 days

Dale added: “The improved design also offers low maintenance costs and minimises spares replacements. Running costs are also low. The scraper blades are designed in a helical curve formation to maximise scraping efficiency and sludge removal.”

Non-standard scrapers will still be available as a range of “bolt-on” packages, priced according to client requirements and specifications. All of Jacopa’s scrapers offer high quality construction and reliable operation, and are suitable for both primary and secondary clarification.

As well as providing new circular tank scrapers, Jacopa can also carry out complete refurbishment of any existing scraper either on site or at the company’s specialist facility in West Bromwich.

Dale said: “We believe we offer the best all-round package and one that allows our clients to take advantage of the benefits of standardisation, driving down costs and response times while retaining quality. Standardisation is now becoming common industry practice, as companies seek to become as efficient as possible to meet cost drivers and Jacopa is pleased to be able to be leading with this best practice approach.”