THE Saxlund Group has received an order from Babcock & Wilcox Vølund A/S, Denmark for the delivery of a state-of-the-art biomass handling system to the Templeborough biomass power plant in Sheffield.

The scope of Saxlund’s order is the design, manufacturing, delivery and commissioning of a dual automatic fuel handling system with reception and transport lines to the boiler, complete with cranes.

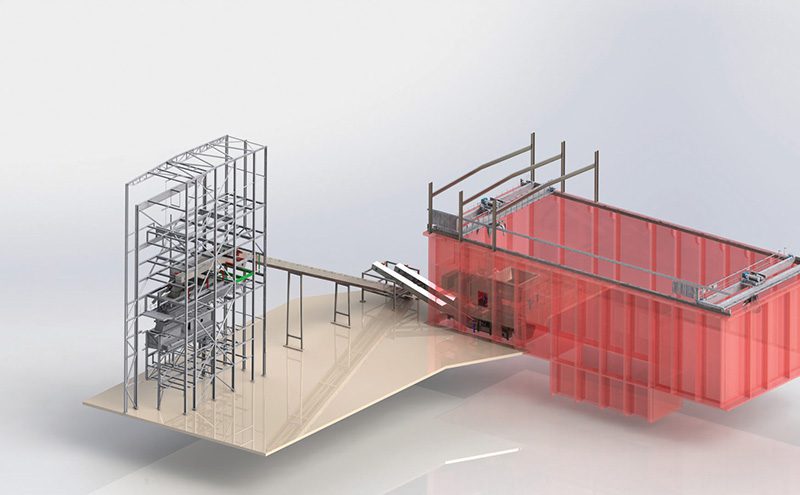

A 3d drawing of the proposed fuel storage and feed system.

The entire fuel feeding system, including wood storage and conveyor systems will be designed to handle multi-fuel waste wood, and will address the priorities of efficiency, minimum maintenance and high availability as well as low emission of dust and noise. Total order value is over 4 million EUR with commissioning and take-over in 2017.

Matt Drew, European Sales Director and UK Managing Director Saxlund International commented: “Saxlund has been contracted to design and install the fuel handling solution which will provide fuel reception, storage and conveyor systems to handle 260,000 tonnes per annum of locally sourced waste wood, to feed the combustion processes. This is our second UK biomass fuel handling contract this year with Babcock & Wilcox Volund, and once again this demonstrates our ability to deliver collaborative international projects combining our engineering and design disciplines in Germany, Sweden and the UK. Due for completion in 2017 the new plant is expected to produce 41MW of green electricity, enough to supply 78,000 homes.”

Drew added: “The Templeborough Biomass Power Plant has a multi-million pound long term deal with Stobart Biomass Products to source, process and supply the biomass feedstock for the plant. Schemes like these have the potential to tick all the boxes – contributing to UK renewable energy targets and a balanced energy economy, as well as waste recycling targets.”

Within the bioenergy sector, Opcon offers everything from the design of complete combined heat and power (CHP) plants to handling systems and incineration plants under the Saxlund brand. Under the SRE brand, systems are supplied for treatment and improved energy efficiency for bioenergy-powered district heating plants, sawmills, pellets producers and commercial greenhouses. The offer also includes flue gas condensation equipment for industrial activities.