A new anaerobic digestion (AD) plant in Norfolk is generating grid-ready biogas to heat 4,500 homes, with propane enrichment supplied by Flogas – a solution the firm says is “simple, reliable and cost-effective”.

With enough capacity to process 4,000 tonnes of organic waste material at any one time, the Future Biogas AD plant in Methwold, Norfolk is described as the biggest facility of its kind in the country. Feedstock for the plant is made up of locally sourced agricultural waste, supplemented by purpose-grown energy crops (including grasses, maize and sugar beet). This feedstock is used to generate high-quality biogas, in a 45-day AD process that takes place in three large on-site silos.

After production, the biogas – which takes the form of pure methane – undergoes propane enrichment to upgrade it and ensure it is suitable for injection into the national gas grid.

When developing the Methwold site, the challenge for operator Future Biogas was finding a propane supplier that could meet its exact requirements, ensuring optimum system performance and long-term gas-to-grid success. Having worked together on several biomethane projects in the past, Future Biogas approached Flogas for a bespoke, turnkey propane enrichment solution.

William Mezzullo, head of projects at Future Biogas, says: “Methwold is the newest of the six biomethane-to-grid projects that we now have in operation, and like all our plants it has very specific propane enrichment requirements. We needed a reliable partner that really understood our needs and could provide a consistent level of service.”

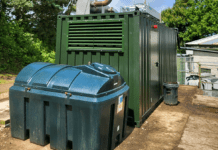

The Flogas project management team specified, designed and installed a complete propane injection system to enrich the biomethane produced at the Methwold plant. The system comprises a propane injection skid (or vapouriser) and five propane storage tanks. It is backed by dependable, ongoing LPG supply from Flogas’ well-established national delivery network. Now fully up and running, the Methwold plant consistently delivers high volumes of gas back to the grid.