FACED with an anaerobic digestion (AD) plant not operating effectively, Dr Stephen Temple – a Norfolk-based dairy farmer and co-owner of Mrs Temple’s Cheeses – enlisted the help of CooperOstlund to advise on a new engine solution to turn unwanted waste into renewable energy. Installed and commissioned in less than 48 hours, the 140kW system now generates more than £220,000 revenue for the farm every year.

Diversifying dairy – a new venture

As part of a diversification venture for their 230 ha dairy farm, Dr Stephen Temple and his wife Catherine made the decision to launch a luxury cheese brand. From Bingham Blue and Walshingham, to Mozzarella and Wighton, Mrs Temple’s Cheeses is now renowned nationwide as one of the UK’s finest artisan producers.

With sales increasing every year, cheese production has quickly become a key source of revenue. However, with a large volume of whey generated during production, combined with cow slurry, fodder beet and maize silage from the farm’s wider operations, waste volumes and disposal costs have also continued to escalate.

Dr Temple therefore decided to invest in an on-site anaerobic digestion (AD) facility, which would turn this waste into methane gas via the natural degradation of organic waste. Using a CHP engine, this gas could be turned into renewable energy and used to power the farm – driving down both energy and waste management costs.

Getting it right from the outset was important, but the project didn’t run as smoothly as expected. The AD plant wasn’t operating effectively, which saw energy production and return on investment figures drop. After researching specialist CHP advisors, Dr Temple came across CooperOstlund – a UK based gas engine specification and maintenance expert – who reviewed the site and advised a more effective solution.

From construction to completion

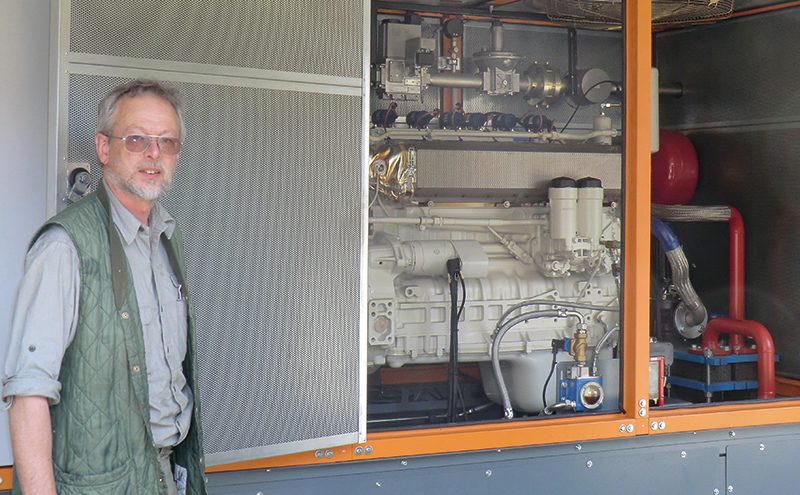

Taking waste volumes, feedstock type and energy requirements into close consideration, CooperOstlund removed the existing biogas engine – replacing it with a considerably more efficient alternative.

The new CHP engine produces 170kW electrical and 198kW thermal energy to heat the dairy, farmhouse and other buildings, as well as warm the cows’ drinking water and power the grain dryer. Excess power is exported directly to the National Grid and, thanks to government subsidies, delivers a financial return of more than £220,000 per year. In addition, the CooperOstlund team provides an ongoing servicing and maintenance contract to keep Dr Temple’s CHP engine running throughout the day and night.

The results

In a short space of time, the AD operation has transformed aspects of the firm’s operations. Dr Temple has completely eliminated organic waste, while becoming self-sufficient in terms of energy overheads. As such, he was recently voted Farmers’ Weekly Green Energy Farmer of the Year, and is now looking towards additional processes to minimise his environmental impact.

“With any AD site, making the right engine choice is hugely important,” commented Dr Temple. “From our own personal experience, you can lose a significant amount of revenue by not getting it right from the outset.

“Thanks to CooperOstlund, our AD site is now generating more than £600 every day. We’re so impressed by the continued support and expertise offered, knowing that we can call upon service technicians day or night.”

Stuart Cooper, director at CooperOstlund, added: “Using insight and experience from across the team, we were able to understand the existing project complications, before effectively installing a completely new engine and getting the site back up-and-running quickly.

“Dr Temple’s AD site is now running at maximum efficiency, delivering an excellent return on investment and helping to minimise waste disposal costs.”