Across a wide range of construction and development projects, geosynthetic drainage systems are increasingly being specified and are said to offer a more effective, economical and eco friendly alternative to traditional solutions. Martin Gilbert, senior sales specialist of geosynthetics at TERRAM, explains why this is the case.

When managing drainage across either a building, structure or even a larger site, it is vital that the correct system is installed. If not, it could lead to severe water damage that could end up incurring significant costs.

Traditionally, granular drainage systems have been commonplace on most developments across the country, with many operating effectively. The solution consists of digging large trenches, inserting a sub surface drainage pipe and then filling the surrounding area with aggregate. This process relies on surface water infiltrating the ground, flowing into the subsurface pipes, and being transported further downstream.

However, there are some common problems when using this type of drainage system. Firstly laying the initial foundations can take a significant amount of time, and finances, specifically in larger developments where there is a requirement to manage a heavy water flow. The time taken to source and transport the raw aggregate material must be considered. When installing a traditional system retrospectively, extra resources may also have to be dedicated to ensure trenches are not dug into any existing power gas or water installations.

There can be further complications after the traditional system is installed. Some smaller piping systems may not be able to cope with heavy rainfall and surface water, when this occurs, it leads to a build up of groundwater behind a structure, which can exert a significant amount of hydrostatic pressure and reduce the integrity of the materials.

Builds ups are commonplace with silt, small stones and building materials causing blockages within the pipes. All can prevent water flowing down the drainage pipes correctly, leading to water coming back up the pipe, potentially causing localised flooding.

Finally, traditional drainage systems do not take account of the rapid rate of urbanisation. In the UK alone, more than 10,000 homes a year are built on floodplains . Traditional drainage systems constructed within these areas simply won’t be able to manage water flow at a fast enough rate, creating flooding within the region, or pushing water further downstream.

Geosynthetics – an introduction

The development of geosynthetics – products that are man-made to support the earth or soil – have assisted in ground stabilisation, containment, protection and erosion control across a wide variety of sectors including highways, railways, coastal areas, landfill, utilities and structural developments.

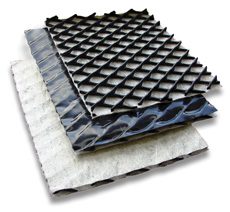

One geosynthetic in particular, geocomposites, is used in construction and civil engineering projects for drainage applications, including, retaining wall structures, edge of highway drainage, landfill, sports field, buried structures, basement walls and roof gardens.

Geocomposite drainage systems are formed by bonding geotextile filters and impermeable membranes to the side of a drainage net. The geotextiles filter water and prevent the ingress of fine soil particles that could otherwise block the core, with the membrane used to prevent the passage of water and gases.

The geocomposite materials consists of HDPE, PE or EVA plastic, all of which produce an impermeable layer that allows even heavy flows of water to stick and run alongside the surface. Due to the flexible nature of the system, more filter layers can be added, if required.

Why use geocomposites?

As geocomposite drainage systems are purposely designed to replace traditional solutions, there are obvious benefits that can be accessed by installing the product, the most evident being during the installation process.

During delivery a geocomposite is the only product involved within the drainage system, whereas a traditional solution requires the sourcing and transportation of primary aggregates and pipe network, both of which can be expensive and time-consuming products with regards to haulage.

Alongside, there is no need to use heavy machinery when installing a geocomposite drain, saving valuable time and costs that can then be used towards the main development of a project. The lightweight nature of the geocomposite also further negates the need for machinery, with the only manual work required involving ‘pinning’ the surface to the ground.

When installing a drainage solution against a vertical structure, such as a retaining wall, traditional system may require a significant amount of aggregate to be filled into the gap behind the wall, which can be a complicated process. However, a geocomposite material is thin and can be easily be slotted behind a retaining structure, without causing any disruption.

With Sustainable Urban Drainage (SuDS) now being used in many developments, especially to reduce risk on flood plains, the role of the geocomposite is key. Traditional drains, cannot guarantee quick run off times however, geocomposite structures provide a large area of impermeable surface, allowing heavily polluted storm water to run off and be stored.

Unlike traditional drainage systems that are almost identical across every site, geocomposite drains are specifically designed to meet the individual drainage requirements of the development. Further benefits include the durability and strength of a geocomposites, which require minimal maintenance throughout its lifespan.

The ideal drainage solution

Granular drainage systems have been providing the solution to basic drainage applications for many years. However, these systems can cause lasting damage if not maintained correctly. Ever since the development of geosynthetic products, the material’s impermeable nature has been identified as ideal for drainage applications.

Overall, geocomposite systems, that consists of layers of geosynthetics materials and filters, offer a more cost effective and carbon neutral option to traditional drainage systems, alongside saving on installation, manufacturing and haulage.

The market for using geosynthetic products is growing rapidly, with many people now seeing the benefits of a system that is changing how drainage systems operate across the world.