At the UK AD & Biogas exhibition on 6 and 7 July Huber Technology will be presenting and advising on “getting more out of your AD plant” by optimising and improving plant performance.

Anaerobic digestion is set to play an increasingly important part in the UK’s renewable energy mix. Process optimisation is seen as a key to delivering operational and bottom line business benefits to plant operators.

Tony Clutten, an AD specialist at Huber Technology, will be available to discuss these kinds of issues with customers, and will be presenting a paper in the purple seminar room titled “Why isn’t my plant running at 100%?”. He will also present a paper on organic recovery and landfill reduction in the R&D Forum. Both events are on Wednesday 6 July.

In the AD process, the firm’s pre-digestion technology is used for screening, washing and compacting of reject material, removing grit and glass, and imported liquid feed screening. Huber’s post digestion technology is used for plastics removal, dewatering, digestate cleaning, and treatment of filtrate.

The key message of “getting more out of your AD plant” by optimising and improving plant performance is supported by options such as removing plastics and contaminants from digestate (helping to achieve PAS 110), removing grit / glass to improve digester performance and reduce wear, and recovering organics from depackaged food waste to improve gas yield and reduce disposal costs.

The company will have a full size Huber Sludgecleaner Stainpress® machine on their stand for customers to come and have a look and understand how the machine works. The Stainpress® is proven technology, says Huber, and now widely used in the AD sector to take out residual plastics left in digestate. These should be removed not only to meet PAS 110 but also for aesthetic reasons.

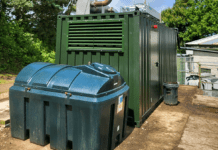

The images above are from a recent installation at an AD site in Wiltshire, where the Huber Sludgecleaner Stainpress® is installed between the digester and the storage lagoon using the head space available in the digester.

Huber says the technology has a successful track record at 9 UK AD sites and 326 in the UK wastewater industry.

More information will be available on stand J502 at UK AD & Biogas 2016 or you can visit the website www.huber.co.uk.