Northants-based pump specialist CDR Pumps is offering a new range of “polymer concrete baseplates” to assist with pump installation, with claimed advantages over conventional approaches such as the use of steel baseplates or not using baseplates at all.

As the firm explains, sometimes not using a base plate of any sort can seem like the easiest option to go with. Why not just use the concrete floor? CDR Pumps says a baseplate is almost always the best option for mounting your pump. It provides you with a sturdy, reliable and level platform on which to mount it. A solid foundation minimises vibration and shifting, keeping everything lined up whilst the pump is in use. A strong foundation will help you maintain uninterrupted and reliable service and should significantly reduce the need for repeated realignment, says the firm.

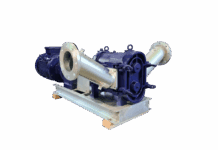

Traditionally, folded or fabricated mild Steel or stainless steel base plates are the most popular choice and are very common but they are not without their problems – corrosion and distortion being two major concerns, and proven to reduce Mean Time Between Planned Maintenance (MTBPM). CDR Pumps is introducing a range of polymer concrete base plates, to assist with pump installation. They are made from Zanite®, a material which combines epoxy resins with quartz aggregate, providing them with a high level of strength and resistance to corrosion.

Traditionally, folded or fabricated mild Steel or stainless steel base plates are the most popular choice and are very common but they are not without their problems – corrosion and distortion being two major concerns, and proven to reduce Mean Time Between Planned Maintenance (MTBPM). CDR Pumps is introducing a range of polymer concrete base plates, to assist with pump installation. They are made from Zanite®, a material which combines epoxy resins with quartz aggregate, providing them with a high level of strength and resistance to corrosion.

Advantages cited for the product include the provision of a flat mounting surface (to 0.002”/foot), significantly improved vibration reduction, ease of installation (saving time and money), improved resistance to corrosion and diaphragming, durability and ASME/ANSI-1991 compliance.

Polymer concrete baseplates are described as still a relatively new addition to the world of pumps but “the effectiveness and reliability is slowly but surely being proven”, says CDR Pumps. They conduct significantly less heat and electricity than their steel counterparts and are suitable for both indoor and outdoor use.