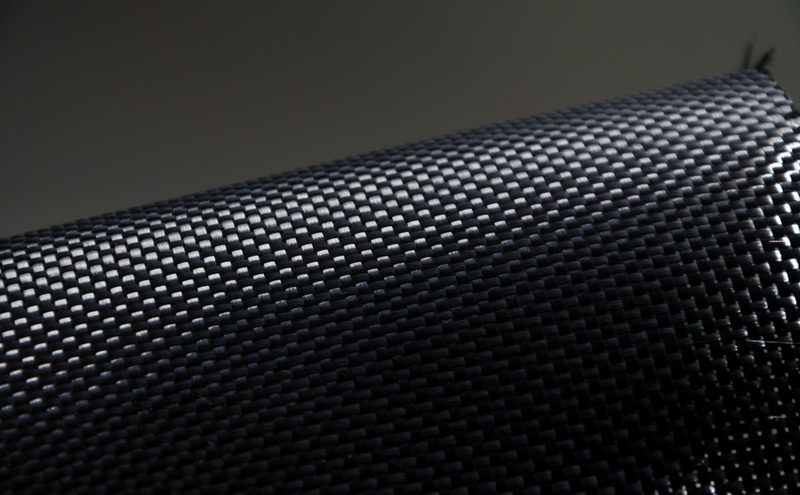

Novel materials like carbon fibre and bioplastics can be stronger, lighter and less resource intensive than traditional materials, so will be key to the low carbon, resource efficient economy to which the government’s new industrial strategy aspires. But unless they are designed for a circular economy, and made ready for recycling and reuse early in their development, they risk disrupting existing recycling systems and creating new waste problems in the future. This is the finding of research recently completed by the think tank Green Alliance, on behalf of Innovate UK, the High Value Manufacturing Catapult and the Engineering and Physical Sciences Research Council.

The report Getting it right from the start: the circular economy for novel materials looked at examples like carbon fibre composites used in cars, bioplastics for packaging, and additive manufacturing technologies such as 3D printing. Its authors say it shows how early consideration of a material’s capacity for reuse, remanufacturing and recycling could help lower costs for British manufacturers and increase their competitiveness.

For example:

– Increasing the quality and quantity of recycled carbon fibres would enable more manufacturers to use the material as it costs 20-40% less than new fibres, enabling them to compete in new markets and with new applications.

– Using more waste materials and by-products to make bioplastics would help UK agricultural, food and drink sectors lower their waste costs

– Commercialising bioplastic production from waste would also mean British manufacturers could compete with the Brazilian sugar cane and subsidised US corn that dominate current supply chains.

– Developing additive manufacturing’s capacity to refurbish broken parts would increase opportunities for repair and remanufacturing businesses, many of which are SMEs distributed around the country.

The report highlights that, to realise these opportunities, the government’s industrial strategy should support new technologies and sectors in three ways:

1. Provide the support and information designers and manufacturers need to think through the whole life cycle of their materials to identify barriers to recovering value from them

2. Support collaboration between sectors and along supply chains to develop new applications for recovered materials

3. Fund research into more recyclable materials and new recovery technologies

Commenting on the report, author Jonny Hazell said:

“If it promotes a circular economy as part of its industrial strategy, the government will go a long way towards boosting employment and economic prospects, not just for scientists and engineers, but for small businesses around the country as well. Our work shows both the threat and opportunity of novel materials, with action needed now to avoid disrupting established resource management systems and increasing the waste of materials. But, equally, addressing this problem will improve productivity and have employment benefits, through developing high value materials and keeping them in use for longer”.

Katie Daniel, Manufacturing the Future Theme Lead, Engineering and Physical Sciences Research Council said:

“EPSRC recognises the importance of research into novel materials to support the future competitiveness and creativity of the UK economy. This report is a timely reminder of the need to incorporate circular economy thinking into materials development so as to make the best use of our resources. EPSRC’s current Delivery Plan highlights moving towards a circular economy as one of our ambitions for making the UK a more productive nation.”